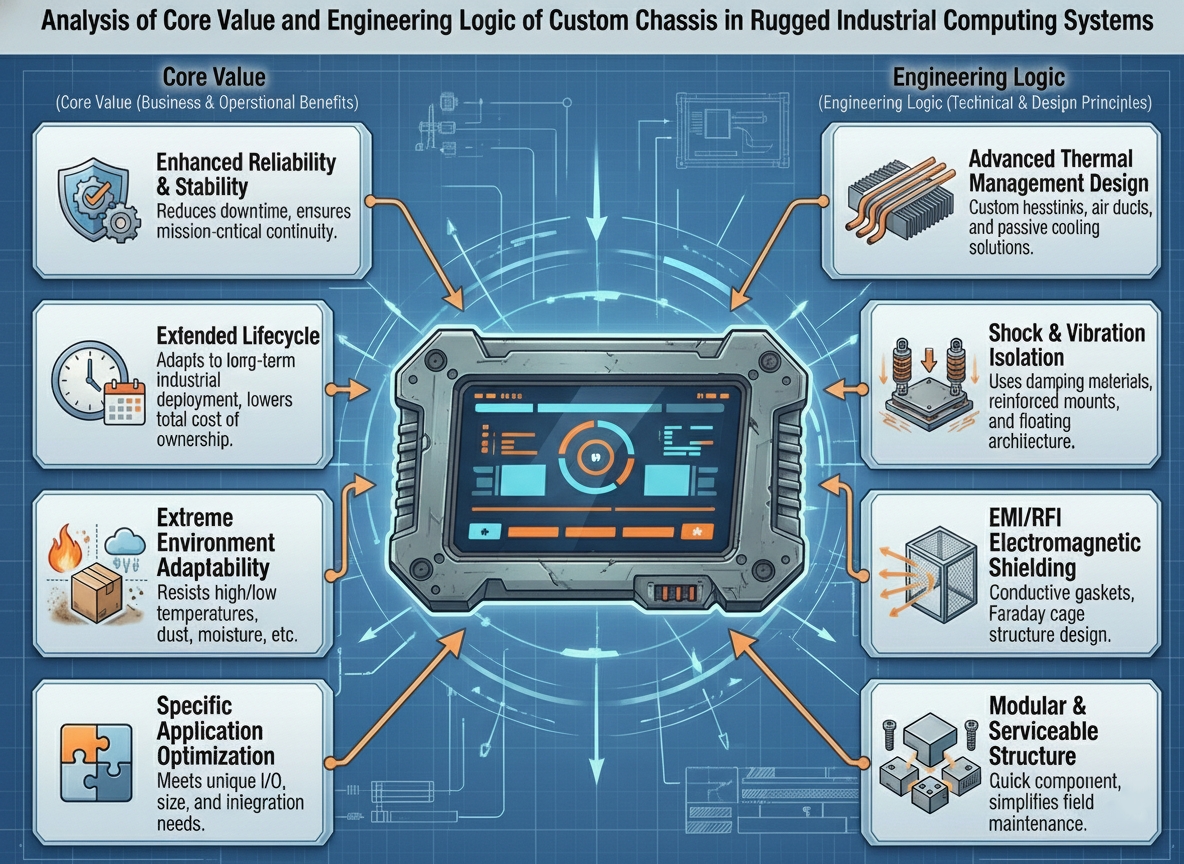

In today’s industrial ecosystem, the physical housing for computing devices—the enclosure—has evolved. Today, it serves as a critical engineering component, integrating environmental protection, thermal management, electromagnetic compatibility, and overall system reliability—far surpassing its former role as a simple packaging container.

Industrial computing environments are harsh. They include extreme temperature swings, constant high-frequency vibration, exposure to corrosive chemicals, and strict hygiene audit requirements. Standard, off-the-shelf enclosures often struggle with these high-performance industrial tasks. The design and manufacturing of custom enclosures is not just about fitting a physical space. It is a deep intervention in the full-lifecycle reliability of computing hardware.

I. Physical Challenges & Material Science Decisions

Industrial computing systems are deployed in tough places. They work in chemical plants, deep-sea drilling platforms, food processing lines, and rail transit hubs. The first line of defense for a custom enclosure is its material. This choice defines the physical survival limits of the device.

1.1 How Material Choice Decides Durability

Material selection must meet specific mechanical and environmental needs. Aluminum alloys (like 5052 or 6061) are a premium choice. Their thermal conductivity is about 205 W/mK. This is about four times better than steel. It enables excellent performance in applications like digital signage and embedded PCs. Anodized aluminum offers high surface hardness. It can also withstand over 500 hours in salt spray tests.

Stainless steel (304 or 316) is essential for hygiene-sensitive industries. Its thermal conductivity (16-50 W/mK) is lower than aluminum. But its non-porous surface resists corrosive cleaners and stops bacterial growth. It is key for meeting IP69K and cleanroom GMP A/B standards.

Magnesium alloy is the top choice for extreme lightweight needs. This includes aerospace or mobile defense platforms. It offers an excellent strength-to-weight ratio and good EMI shielding.

Non-metallic materials like Polycarbonate (PC) are very light and electrically insulating. However, their thermal conductivity is very low (~0.2 W/mK). They are usually only for handheld devices or small wireless sensors. They often need extra coatings for EMI shielding.

1.2 Structural Geometry & Defensive Redundancy

Custom enclosure design goes beyond simple boxes. Engineers use geometric reinforcement. They add features like ribbing or honeycomb patterns to panels. This greatly increases torsional stiffness and compressive strength without adding much weight. This design ensures minimal casing deformation. It protects internal PCBs from cracks or solder joint failures caused by stress.

II. Thermal Engineering – The Core Mission

Heat is the number one enemy of industrial computing. Components generate heat during operation. If this heat is not removed, it causes problems. These include thermal throttling, system instability, and permanent damage.

2.1 The “10-Degree Rule” & The Economics of Thermal Management

A key rule in electronics reliability states: for every 10°C increase in ambient temperature, the average lifespan of electronics halves. A system might last 10 years at 25°C. But in a sealed box without cooling at 45°C, its life could drop to just 2.5 years. Therefore, thermal design is not just technical. It is a financial decision impacting Return on Investment (ROI).

2.2 From Passive Cooling to Advanced Techniques

In dusty environments, custom enclosures often use passive cooling. They employ integrated heat fins to maximize surface area. They use the “chimney effect” for natural airflow.

When passive cooling is not enough, custom solutions apply advanced tech. Heat Pipes use fluid phase change. They offer very high thermal conductivity. They are perfect for removing local hot spots in tight spaces. Thermoelectric Coolers (TEC/Peltier) act as solid-state heat pumps. They can cool sensitive sensors below ambient temperature.

For high-power equipment, Vapor Compression Cooling (VCC) uses refrigerant cycles. It provides strong cooling for medical lasers or solar power stations. New innovations include 3D-printed lattice heat exchangers. Their complex internal channels increase heat exchange area. They can reduce system size by 10-35% compared to standard racks. This “isolated” design keeps external air out of the internal clean chamber. It allows efficient cooling in a fully sealed unit.

III. Sealing & Protection Ratings: From IP65 to IP69K

Industrial computing devices face many threats. These include water ingress, oil accumulation, and harmful dust. Custom enclosure sealing technology is the final guard. It prevents electrochemical corrosion or short circuits inside.

3.1 The Engineering Details of Sealing

Sealing is more than just an O-ring. In custom enclosure manufacturing, “Form-In-Place Gasket” (FIPG) is a key technology. A high-precision robot applies a continuous bead of polyurethane or silicone into a complex groove. It cures to form a seamless, durable, and aging-resistant pressure seal. This seal withstands long-term mechanical stress. It maintains its rated protection level for the product’s entire life.

3.2 Understanding Protection Standards

Choosing a custom enclosure requires understanding standards. IP67 or IP68 ratings focus on immersion protection under static water pressure. They allow operation in water over 1 meter deep. They suit marine sensors or underground facilities prone to flooding.

IP69K is the highest rating for dynamic wash-down environments. It requires the enclosure to withstand high-pressure, high-temperature spray from multiple angles. The test uses water at 1450 psi and 80°C. This requirement is essential for food processing, pharmaceuticals, and heavy machinery cleaning. These places need extreme wash-downs for sterility.

IV. Mechanical Resilience: Custom Anti-Vibration & Shock Solutions

Industrial computers often mount on vibrating machine tools, heavy trucks, ship engine rooms, or locomotives. Constant physical stress can cause structural failure. It can also transmit vibrations. This may loosen internal connectors or break PCB traces.

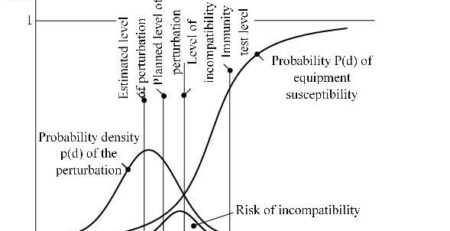

4.1 Survival Under MIL-STD-810H

The military standard MIL-STD-810H emphasizes custom testing for specific missions. Custom enclosures use Finite Element Analysis (FEA) simulation during design. Engineers add structural damping or adjust wall thickness in specific areas. This ensures the natural resonant frequency avoids the equipment’s operating frequency range.

4.2 Selecting & Applying Damping Materials

To protect sensitive components, custom enclosures integrate specific damping materials. Sorbothane® is a superb viscoelastic polymer. It efficiently converts mechanical energy into heat. Its low transmissibility makes it ideal for protecting processors from strong impacts.

Polyurethane foam (like PORON®) has slightly lower strength. But it resists compression set very well. It stays stable under long-term squeeze forces. For environments with huge temperature swings, silicone foam (like BISCO®) is common in aerospace and rail. It offers a wide temperature range and fire resistance. 3M’s viscoelastic foil tape often attaches to metal panels. It acts as a constrained layer damper. It effectively reduces noise and micro-vibrations from resonance.

V. Deep Integration with Human-Machine Interface (HMI)

Industrial touch displays are the core interaction window. Their enclosure design directly affects visibility and responsiveness.

5.1 Optical Bonding: A Leap in Visuals & Durability

Custom enclosures often integrate Optical Bonding. This process injects optical gel (OCR/OCA) between the display and its cover glass. It eliminates the air gap. This design increases image transmittance to over 98%. It prevents internal condensation from temperature differences. It also greatly boosts the display’s physical impact resistance.

5.2 Industry-Specific Touch Technology

Custom enclosures allow touch technology matching operational habits. Projected Capacitive (PCAP) technology uses optimized algorithms. Combined with thicker cover glass (e.g., 3mm), it allows precise operation even with latex or thick leather gloves.

In extremely rough industrial settings, Resistive touch screens remain relevant. They respond to physical pressure. This allows operation with a fingernail or any stylus.

VI. System Integration Logic: From Bare Chassis to All-in-One

A custom enclosure is more than a protective shell. It is the foundation for system assembly.

Integrating a display as a Bare Chassis into a larger custom cabinet removes redundant bezels. It allows for flush mounting with the control panel. This eliminates crevices where contaminants can gather. It also lets the entire metal cabinet act as a heat sink extension. This dramatically improves cooling efficiency.

VII. The Economics of Reliability: Total Cost of Ownership

In industry, downtime costs are extremely high. Each hour of stoppage can mean tens of thousands in losses. The goal of investing in custom enclosures is to optimize Total Cost of Ownership (TCO).

Standard enclosures may have a lower initial purchase price. But their poor environmental fit often needs frequent manual modifications and maintenance. Their expected lifespan is often only 3-5 years.

In contrast, custom rugged enclosures involve higher initial engineering costs (NRE). However, their “plug-and-play” fit reduces installation costs. Their passive cooling and full-seal design need almost no daily maintenance. Their operational life can reach 10-15 years.

By increasing the system’s Mean Time Between Failures (MTBF) from an industry average of 50,000 hours to over 120,000 hours, businesses can reduce long-term TCO by 15-20%.

VIII. Industry 4.0 & The Rise of the Smart Enclosure

With the Fourth Industrial Revolution, enclosures are evolving into intelligent, self-diagnosing nodes.

Embedding sensors inside the enclosure allows real-time condition monitoring. These sensors track temperature, humidity, acceleration, and current. This “smart enclosure” can predict the aging failure of its own seals. It can also monitor the health of nearby machinery through vibration spectrum analysis.

For example, built-in sensors can detect tiny vibrations deviating from a baseline. AI algorithms can then send an alert weeks before a catastrophic failure. This shifts maintenance from “fix after failure” to “predictive maintenance.”

IX. Case Study: Industry Practice by Shenzhen Golden Margins

The practice of Shenzhen Golden Margins shows how custom enclosures solve industry pain points.

- Ultra-Wide Bar Display Applications: For narrow spaces like retail shelves or subway doors, they created custom stretched enclosures for 15.3-inch and 38-inch displays. These housings feature IP65 front sealing and 1500 nits high brightness. They solve the dual challenges of special-ratio installation and outdoor sunlight visibility.

- Laser Cutting Interactive Terminal: For high-vibration, EMI-sensitive environments, they used a brushed aluminum fully sealed enclosure. A four-reinforced-hook design enables 5-minute quick embedding. This saves significant on-site installation time and ensures stability in heavy industrial settings.

- Medical & Cleanroom: They provide True Flat, seamless enclosures. These eliminate physical grooves where disinfectant could pool and corrode internal circuits. They support 10-point touch and withstand frequent chemical sterilization. They perfectly meet the stringent demands of medical labs.

For rugged industrial computing, the custom enclosure is the foundational bedrock ensuring system functionality. From precise material matching to deeply integrated thermal systems, it builds a bridge between physical safety and data reliability.

In the modern industrial race for higher precision, lower downtime, and longer operational life, investing in high-performance custom enclosure solutions has become the true standard. It measures whether an industrial computing system is genuinely “rugged.”

We hope you found these fundamentals on touchscreen or panel PCs informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical-grade, sunlight-readable, open-frame, and waterproof touchscreens, as well as other unique touchscreen or panel PC designs. You can learn more about our services here or by calling us at +86 755 23191996 or sales@goldenmargins.com.