What is Optical Bonding?

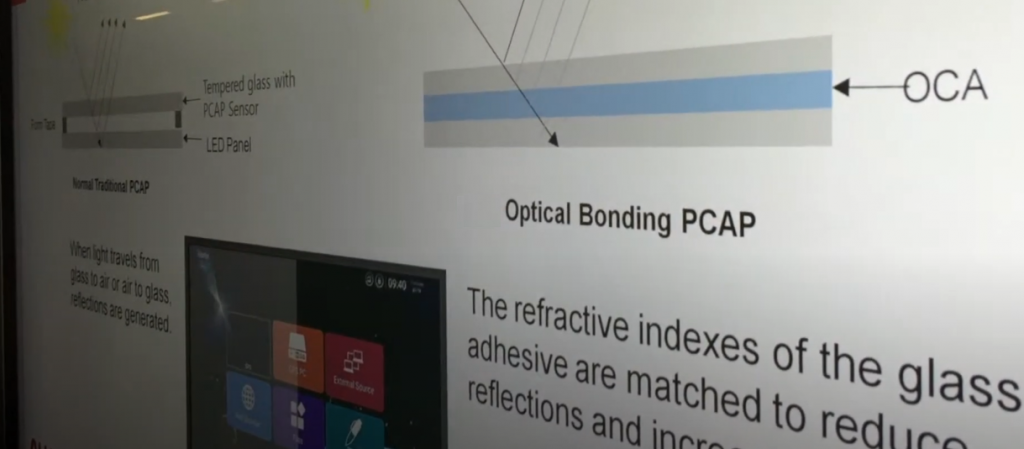

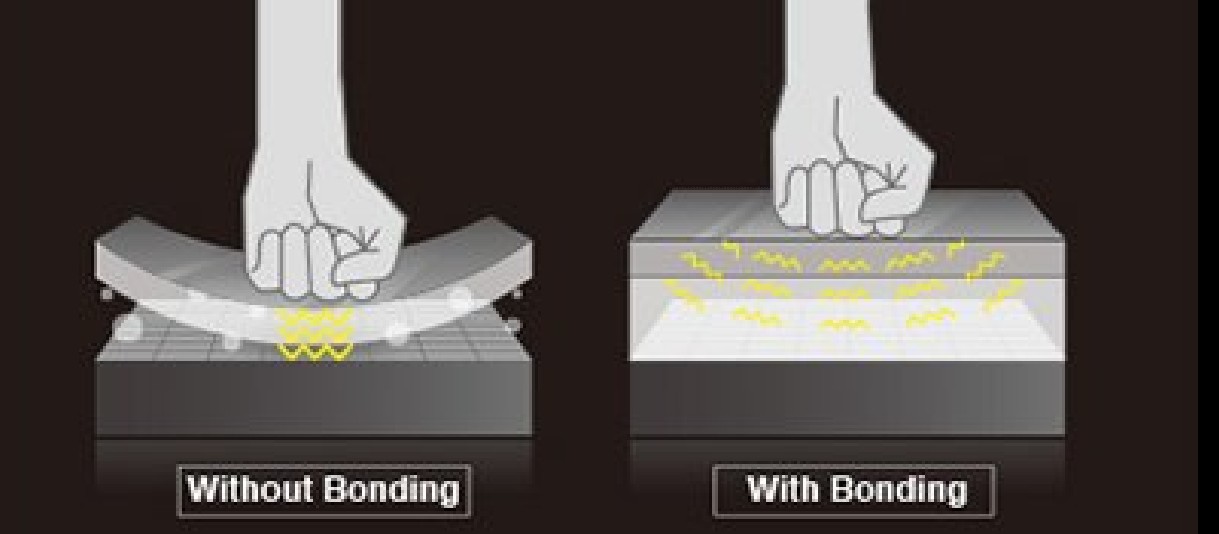

Optical bonding is a technology that injects special glue in the display glass or touch screen and TFT liquid crystal (TFT) panel and coated with a layer of resin (OCR) or film (OCA), bonding into a solid laminate without gaps or bubbles. When selecting screens for any project, you should evaluate the environmental and operational conditions that screens will have to endure. Industrial-grade screen and panel PCs are rugged with all types of features and can withstand any type of application. One property that can be considered is optical bonding.

Optical bonding is widely used in the medical, military, transportation and retail sectors where higher performance displays are required due to harsh environments. Optical bonding is suitable for industries that need to use robust displays in high reliability environments or need to use displays in high ambient light conditions. The optical bonding process is particularly suitable and more efficient for equipment that operates outdoors or in bright light.

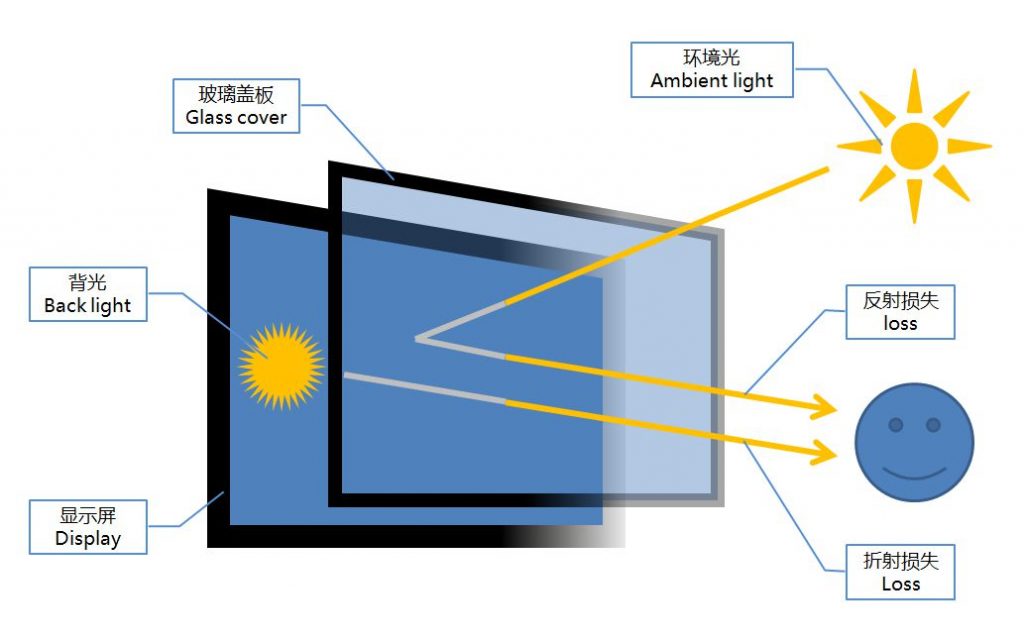

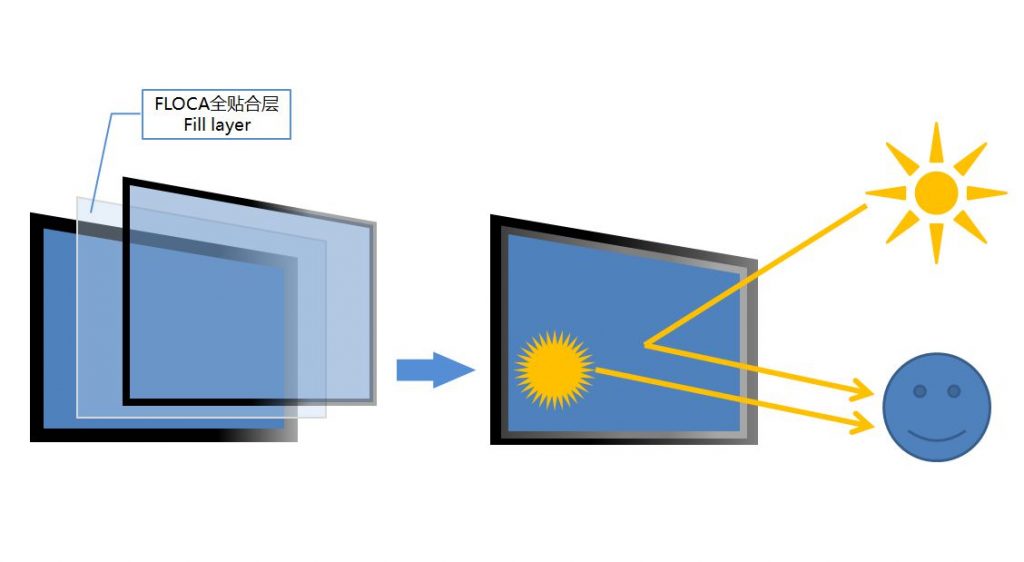

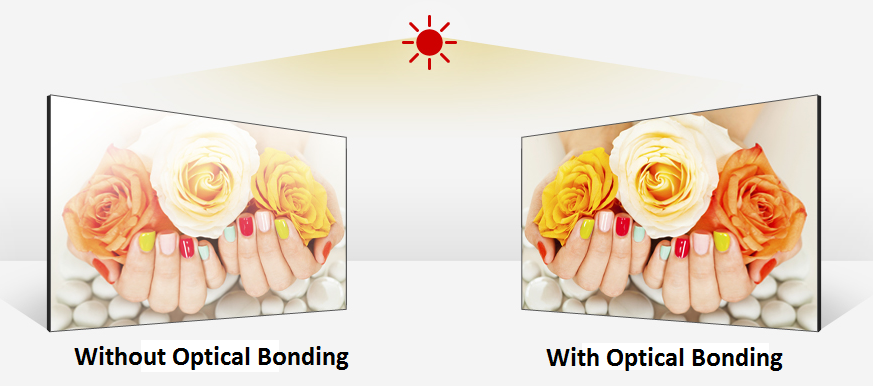

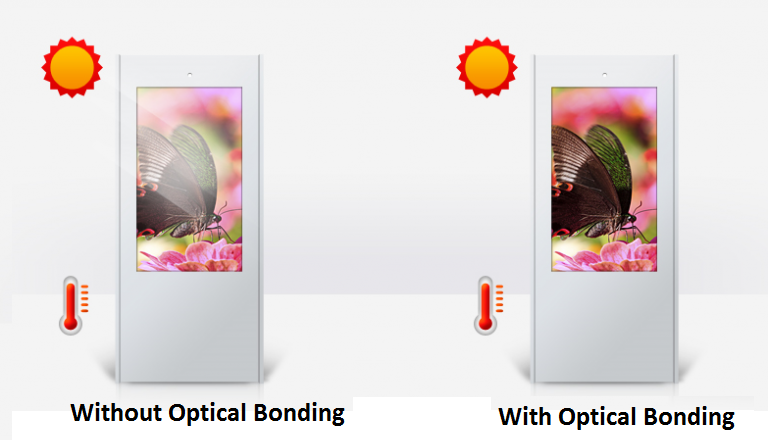

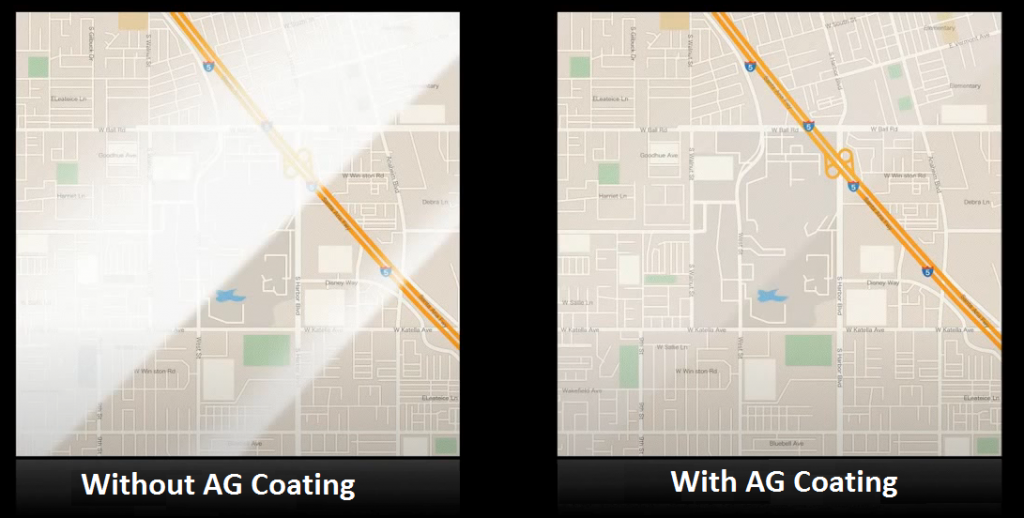

Comparison of strong light irradiation between LOCA full lamination and traditional air gap bonding.

LOCA optical lamination fills the organic silicone between the LCD module and the touch screen which the light reflection loss is small. Therefore, the display screen has a higher contrast and superior display effect under the irradiation of ambient light. It effectively avoid condensation, dust or other impurities in the interlayer of the display screen.

Optical Bonding VS Non-Optical Bonding

At least increas 10% Brightness of panel

Sunlight readability (Text could be seen within 1m away from sreen)

The image & content will not be blur even the Viewing Angle keeps changed

AG coating reduces reflections. More Clarity More Eye care

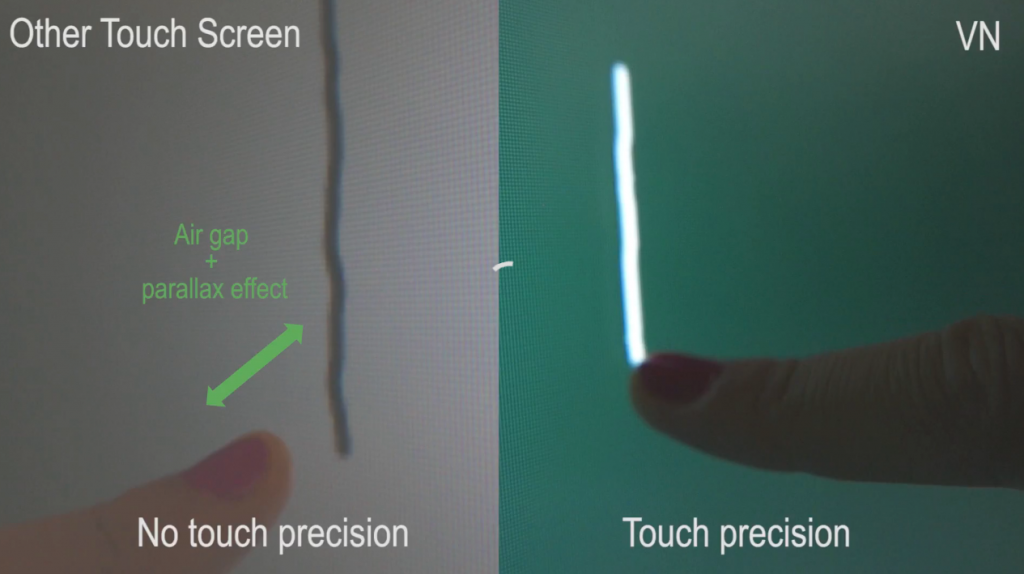

More accuracy and More faster for drawing and Writing No delay, No gap between finger and drawing

Be more able to withstand the external Impact and Scratched

Our Optical Bonding Service

Organic Sillicone Glue (Germany Wacker Glue)

1) Be able to withstand the harsh ambient (Working Temperature: -35℃-110℃)

2)The Glue will not change to yellow even working under high temperature

3) Be able to prevent bubble created inside between TP and LCD.

4) Be able to prevent yellow screen.

Relative Products

- Box PC

Industrial Barebone System Mini Pc Linux Box PC barebone mini computer for AI Visual Positioning Equipment Automation

Embedded PC Box provide switches, indicator lights, and USB 2.0 ports . Lockable, and provides easy-to-identify color on and off-state markings to prevent omissions. Detachable dust-proof net

Read MoreQuick View - Box PC

Industrial All-in-one Embedded PC Box Full aluminum case fanless cooling PC 6 RS232 COM i3 i5 i7 industrial mini pc support 4K display

Embedded PC Box provide switches, indicator lights, and USB 2.0 ports . Lockable, and provides easy-to-identify color on and off-state markings to prevent omissions. Detachable dust-proof net

Read MoreQuick View - 98‘’ conference all-in-one machine, Conference&Education Integrated Machine

98 Inch E-Learning Class Meeting Room IR Smart Multi-Media Interactive LCD LED Display with 4K Interactive Whiteboard

75-inch 4k All-in-one Conference displays with Aluminum alloy outer frame, sandblasted anodized surface, iron shell back covers, active heat dissipation; ultra-narrow sandblasted face frame, ultra-narrow design

Read MoreQuick View - 86‘’ conference all-in-one machine

Multi-Functions Conference All-in-one Touch Screen Smart TV IR Interactive Whiteboard Advertising Kiosk

86inch Multi-Functions Conference Touch Screen has a front-mounted expansion port: Front-mounted one-button start switch realizes three-in-one TV, computer, and energy-saving integrated switch function; convenient operation, simple and elegant appearance.

Read MoreQuick View - 75‘’ conference all-in-one machine, Conference&Education Integrated Machine

75 inch 4k resolution wall mount smart board interactive whiteboard digital signage meeting room display

75-inch 4k All-in-one Conference displays with Aluminum alloy outer frame, sandblasted anodized surface, iron shell back covers, active heat dissipation; ultra-narrow sandblasted face frame, ultra-narrow design

Read MoreQuick View - 65‘’ Conference all-in-one machine, Conference&Education Integrated Machine

All-in-one OPS interactive whiteboard infrared touchscreen smart electronic whiteboard marker for conference

Dual system conference display with built-in WIFI modules on the Android motherboard and PC in the machine, which are convenient for users to perform wireless transmission and network operations through…

Read MoreQuick View - 55‘’ conference all-in-one machine, Conference&Education Integrated Machine

55″ 65″ 75″ 86″ 98″ 4K touch TV interactive all-in-one whiteboard online education conference machine

55inch LCD display Android OS Dual-system 4K Digital multi-touch Multi-functions Multi-Media Interactive LCD Display has 3mm physical tempered anti-glare glass; strengthens the visual effect, improves the touch experience; standard 20-point…

Read MoreQuick View

GET A FREE QUOTE TODAY

Never Miss Any Deals