In today’s digital era, human-machine interfaces have become indispensable components in mission-critical applications, including industrial control, vehicular systems, medical equipment, and outdoor displays. As application scenarios grow more complex and environmental conditions become harsher, the performance limitations of traditional display modules are increasingly apparent. Optical bonding technology stands as the key solution to break through these constraints.

I. Technical Principle: The Revolutionary Breakthrough of Refractive Index Matching

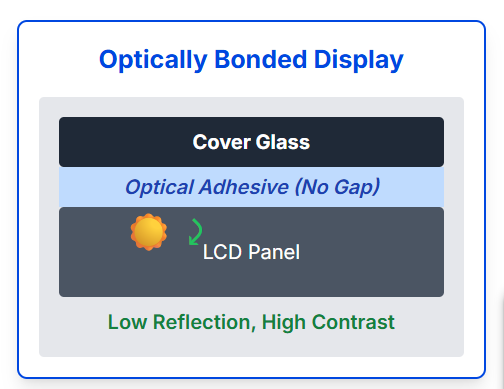

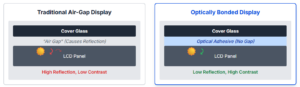

The core of optical bonding technology lies in its unique refractive index matching mechanism. Traditional air-gap bonding retains an air layer between the cover glass and the display panel. The significant difference in refractive index between air and glass causes intense reflection and refraction of light at the interface. According to optical principles, this interfacial reflection not only causes luminance loss but, more severely, produces glare, significantly reducing display contrast and color accuracy.

Optical bonding technology creates a revolutionary optical pathway by filling the air gap with Optically Clear Adhesives. These specialized adhesives are precisely engineered to have a refractive index highly matched to the glass substrates, allowing light to pass between different media with almost no reflection. This innovative design reduces internal reflection by approximately 90%, achieving a qualitative leap in display performance.

II. Materials Science: Technical Characteristics of OCA and LOCA

The implementation of optical bonding technology relies on two key classes of materials: Solid Optical Clear Adhesives (OCA) and Liquid Optical Clear Adhesives (LOCA/OCR). Each offers distinct characteristics suited for different application scenarios.

Solid Optical Clear Adhesives (OCA) exist as pre-formed films, offering advantages of relatively simple processes and stable yield rates. However, their geometric adaptability is limited, making them primarily suitable for flat, thin display modules. When encountering complex shapes or designs with borders, OCA struggles to achieve perfect filling.

In contrast, Liquid Optical Clear Adhesives (LOCA) stand out for their exceptional adaptability. LOCA can fill irregular surfaces and complex structures, providing more comprehensive sealing protection. More importantly, high-performance LOCA possesses excellent weather resistance, UV resistance, and an ultra-wide temperature operating range, making it the ideal choice for demanding environmental applications like automotive displays.

GoldenMargins utilizes silicone adhesive from Germany’s Wacker Chemie AG, setting the trend in optically bonded displays. With superior performance in reflection suppression, contrast enhancement, and overall readability, our solutions markedly outperform conventional non-bonded screens. Whether for esports entertainment, industrial control, or customized scenarios, they deliver consistent and stable 24/7 operation.

III. Manufacturing Process: The Pursuit of Ultimate Precision and Cleanliness

The manufacturing process for optical bonding exemplifies the modern industry’s pursuit of ultimate precision and cleanliness. The entire process must occur in a high-class cleanroom environment, as any microscopic particle can cause a critical defect. Precise lamination under vacuum is a crucial step to ensure a bubble-free bond, placing extremely high demands on equipment accuracy and process control.

For liquid optical adhesive bonding, the process complexity increases significantly. From precise dispensing control to the leveling process in a vacuum environment, each step requires accurate parameter control and extensive experience. Factors such as the adhesive’s viscosity, surface tension, dispense volume, and curing conditions are interdependent, collectively determining the final product yield.

IV. Performance Advantages: Comprehensive Technological Breakthroughs

The performance improvements brought by optical bonding technology are comprehensive and significant. In terms of optical performance, by eliminating internal reflections, display brightness is effectively enhanced, and contrast is significantly improved. Especially in outdoor bright-light environments, optically bonded displays maintain excellent readability, an advantage unattainable by traditional air-gap solutions.

Regarding the touch experience, optical bonding eliminates the parallax effect. Due to the zero-distance coupling between the touch layer and the display layer, users enjoy precise and natural touch operation. This advantage is particularly important in industrial control and medical equipment requiring precise positioning.

The improvement in structural performance is equally impressive. Optical adhesives not only serve as a connection but also act as structural reinforcement, significantly enhancing the display module’s impact and vibration resistance. Furthermore, the complete seal effectively prevents the ingress of dust, moisture, and condensation, ensuring long-term reliability of the equipment in harsh environments.

V. Application Scenarios: The Preferred Solution for Key Industries

In the field of automotive displays, optical bonding technology has become standard for high-end models. Its excellent anti-glare performance ensures drivers can clearly read information under various lighting conditions, while its outstanding temperature stability and shock resistance meet the stringent reliability requirements of automotive electronics.

Industrial and military applications also benefit greatly from this technology. In these scenarios, display equipment must withstand extreme temperatures, strong vibrations, and potential impacts. The structural reinforcement and environmental protection provided by optical bonding make it the preferred choice.

Medical imaging equipment demands the highest standards of display performance. Color accuracy, brightness stability, and long-term reliability are all crucial for diagnostic accuracy. Optical bonding technology comprehensively meets these stringent requirements.

VI. Economic Analysis: A Rational Choice for Long-Term Value

Although the initial cost of optical bonding is significantly higher than traditional solutions, the long-term value it brings is equally notable. In mission-critical applications, equipment failure can lead to substantial economic losses or even safety risks. By enhancing reliability and service life, optical bonding technology effectively reduces the total cost of ownership over the entire lifecycle.

Particularly in application scenarios requiring high-brightness backlighting, optical bonding can, by improving optical efficiency, can reduce the power requirements for the backlight, thereby achieving system-level energy consumption optimization. This system-level cost-effectiveness is especially prominent in large projects and long-term operations.

VII.Future Outlook: Technological Innovation and Market Expansion

With the continuous development of new display technologies, optical bonding is also constantly evolving. Emerging display technologies like Mini-LED and Micro LED place higher demands on bonding processes, while simultaneously creating new development space for optical bonding.

In the future, we may see the emergence of more functionally integrated optical adhesive materials, such as adhesives with integrated light-conversion capabilities, which will further expand the possibilities of display technology. Simultaneously, as process technologies mature and economies of scale emerge, optical bonding technology is expected to penetrate broader consumer-grade markets.

VIII. Conclusion

Optical bonding technology represents the highest level of display module packaging processes. Through precise material design and process control, it overcomes the inherent optical defects and reliability issues of traditional display technologies. While it demands advanced technical expertise and substantial initial investment, the value it delivers far exceeds the cost in applications where stringent performance and quality standards are required.

As technology continues to advance and market understanding deepens, optical bonding technology is destined to demonstrate its unique value in more areas, driving the entire human-computer interaction experience to a higher level.

Quality First, Excellence in Details.

From the initial selection of WACKER silicones, goldenmargins has infused superior quality into every detail. Leveraging professional expertise and stringent production standards, our optically bonded displays consistently meet your high requirements by exceeding expectations. This is not just a promise, but a result verified by rigorous process controls—ensuring every product possesses military-grade stability and reliability.

Ready to Experience a Superior Display Solution?

Explore our full range of display products, or contact our team immediately to tailor an exclusive solution for you.