The core functions of industrial touch displays rely on the precise perception and transmission of touch signals by the Conductive Layer Material. As the key carrier connecting user operations and internal circuits, the conductive layer must simultaneously meet the requirements of high sensitivity, high stability, and long life, and must adapt to harsh industrial environments such as wide temperature, high humidity, vibration, and chemical corrosion. Its selection is directly related to the reliability and service life of the product, and is an important link in industrial design that cannot be ignored.

The performance of the Conductive Layer Material must meet four core indicators. Electrical performance is the basis, requiring the square resistance to not exceed 100Ω, and the resistivity fluctuation to be controlled within 5% to ensure signal transmission efficiency and stability; optical performance must take into account high transmittance and no interference fringes to avoid affecting display clarity; mechanical performance requires a breaking strength of not less than 100MPa and a breaking elongation of not less than 5% to withstand vibration, impact, and frequent pressing; environmental adaptability must cover a wide temperature range of -40℃ to 85℃, non-oxidation at 95%RH humidity, and resistance to UV and chemical solvent corrosion to ensure stable operation under complex working conditions.

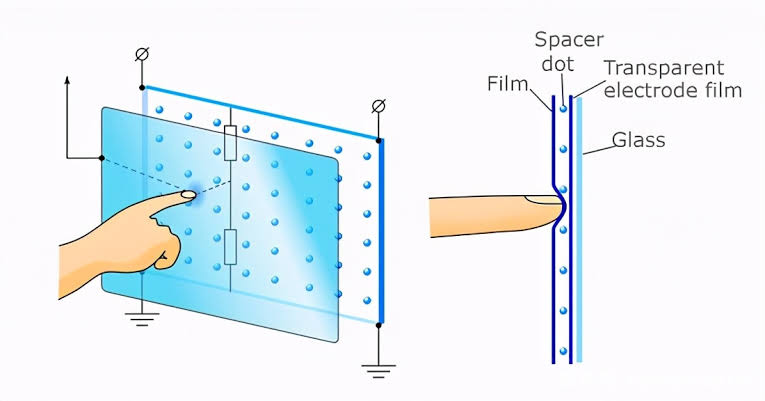

The characteristics of mainstream conductive layer material is vary significantly, and selection must be based on scenario requirements. Indium tin oxide (ITO) is the traditional mainstream, accounting for 70% of the market share. It has advantages such as low square resistance and mature process (achieved through magnetron sputtering process), but it is mechanically brittle, easy to crack, indium resources are scarce, costly, and easy to fail in high temperature and high humidity environments. It is only suitable for conventional indoor scenarios. Among metal-based nanomaterials, nano silver wires have high flexibility, wide temperature range, and corrosion resistance as their core advantages. They are suitable for foldable devices or extreme environments, but they are expensive and have the risk of silver migration; copper grids have conductivity close to silver and are resistant to oxidation, but line width control is difficult and mechanical strength is lower than silver, making them more suitable for large-size low-cost scenarios. New composite materials such as graphene/silver nanowire composite films and conductive polymers doped with metal particles have shown potential in low-precision touch or indoor fixed equipment scenarios, but they need to solve problems such as limited conductivity and poor temperature resistance.

Conductive Layer Material selection needs to follow the logical chain of demand decomposition-performance matching to process verification. First, clarify the scene requirements: nano silver wire or copper mesh is preferred for outdoor or extreme temperature difference scenes; ITO can be selected for indoor fixed equipment; flexible materials such as nano silver wire are required for frequent bending or impact scenes; ITO can be used for static scenes. Secondly, benchmark the material performance and combine the budget and display requirements. Finally, verify the process adaptability. For example, ITO relies on vacuum coating equipment and is suitable for standardized production lines; nano silver wire requires coating and curing processes, which is suitable for medium-volume flexible screens; copper mesh requires precision lithography, which is suitable for high-precision large-size screens. At the same time, it is necessary to pass temperature and humidity cycles, mechanical impact, salt spray tests, and life tests to ensure long-term reliability.

There is no optimal solution for the selection of industrial-grade Conductive Layer Material, only the most suitable solution. ITO occupies conventional scenarios with mature processes and low costs, nano silver wire dominates high reliability requirements, and copper mesh has significant potential in large-size and low-cost fields. The final decision needs to be based on specific scenarios, balancing performance, cost and process, and verifying reliability through prototype testing to ensure the long-term stable operation of industrial touch displays under complex working conditions.