1. The importance of using industrial panel computer in the Low-Temperature Environment

In most cases, cooling is actually good for computers, which can avoid overheating problems. However, there are some unique hazards for ordinary computers in low-temperature environments and that is why rugged mini PCs or rugged industrial panel computers are so important for sub-optimal environments.

What will happen when the computer is cooled down? For standard components, the cooling circuit actually expands and deforms under the sudden burst of heat and electricity when being powered on.

Any parts made of liquid crystal (such as LCD) will also be frozen and shattered. The likely overlooked danger of cold computers is that the hard drives use fluid dynamic bearings to spin physical hard disk platters. If the fluid in the bearing becomes thicker, the disc will spin down and the computer will read in and retrieve data at a very slow rate.

Finally, low temperatures will produce more condensation inside the computer. The water produced in the process may subsequently cause short circuits and corrosion.

2. Advantages of industrial panel computer at low temperatures

The specialized and durable industrial panel computers can run at a lower temperature and are less susceptible to most of these threats. The sealed enclosure and fanless design can prevent most of the condensation, and the military-grade components of this type of computer are less likely to warp.

Finally, because industrial panel computers are usually durable and equipped with more easy-to-use SSD hard drives, so there are no hard disk platters or fluid bearings, which will not bring harmful effects on data storage.

3. Special LCD optical bonding technology

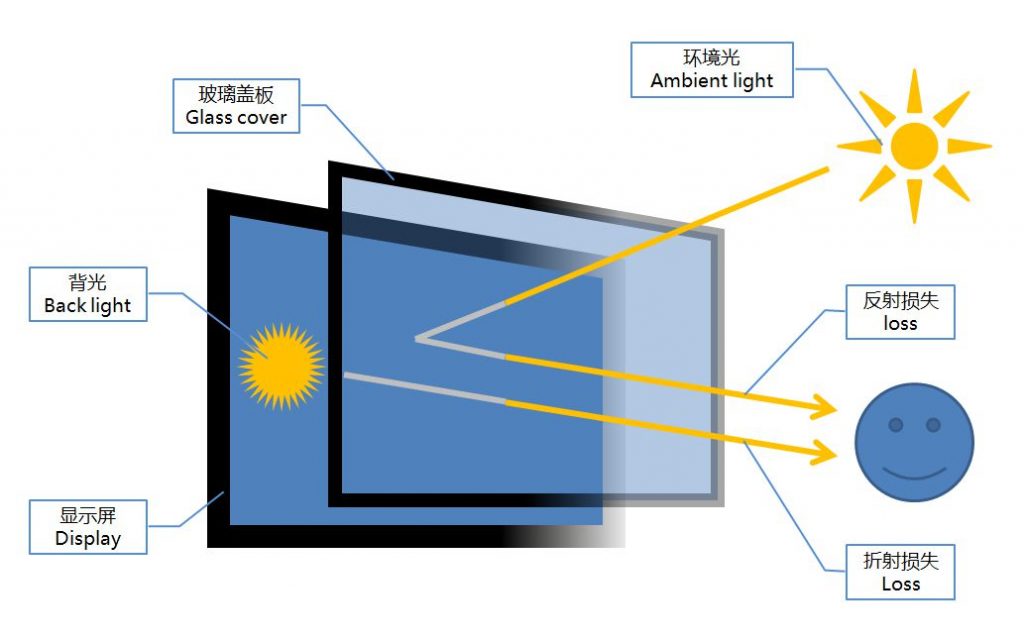

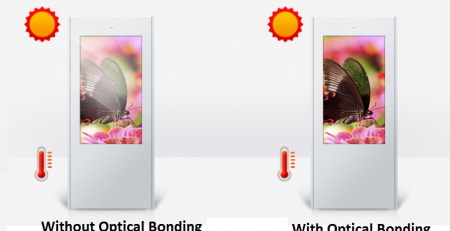

What is Optical Bonding?

Optical bonding is a technology that injects special glue in the display glass or touch screen and TFT liquid crystal (TFT) panel and coated with a layer of resin (OCR) or film (OCA), bonding into a solid laminate without gaps or bubbles. When selecting screens for any project, you should evaluate the environmental and operational conditions that screens will have to endure. Industrial-grade screen and panel PCs are rugged with all types of features and can withstand any type of application. One property that can be considered as optical bonding.

Optical bonding is widely used in the medical, military, transportation, and retail sectors where higher-performance displays are required due to harsh environments. Optical bonding is suitable for industries that need to use robust displays in high-reliability environments or need to use displays in high ambient light conditions. The optical bonding process is particularly suitable and more efficient for equipment that operates outdoors or in bright light.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com

Comments (444)

Your article helped me a lot, is there any more related content? Thanks!

I love the efforts you have put in this, appreciate it for all the great articles.

UID_74743238###

Ini dia! 🎉🎉 ASN BKN Ubah Pola Kerja yang baru dan efisien! 🎉🎉.

UID_83344528###

Inilah 🎉🎉 Pupuk Inovatif Kebun Riset Kujang yang bikin Wamen BUMN bangga! 💪🏻🇮🇩

UID_25978847###

situs terbaik hanya di slot gacor agentotoplay

UID_95859078###

Baru-baru ini, para pemain Mahjong Wins 3 dikejutkan dengan bocoran RTP yang diklaim bisa meningkatkan peluang kemenangan secara signifikan. Banyak yang percaya bahwa informasi ini membantu mereka mendapatkan hasil yang lebih konsisten dalam permainan. Jika Anda ingin tahu lebih lanjut, cek bocoran RTP Mahjong Wins 3 hari ini dan lihat apakah strategi ini benar-benar efektif.

UID_57331425###

Skandal terbaru mengguncang komunitas pecinta game slot setelah seorang admin terkenal, Rachel, dikabarkan tertangkap membocorkan pola kemenangan Gate of Olympus. Banyak yang bertanya-tanya apakah informasi ini benar-benar akurat atau hanya sekadar rumor yang beredar di kalangan pemain. Simak lebih lanjut detailnya dalam artikel admin Rachel tertangkap bocorkan pola Gate of Olympus.

UID_17136916###

Kisah inspiratif datang dari seorang tukang ojek online asal Tangerang yang berhasil membawa pulang hadiah fantastis setelah bermain Mahjong Ways 2. Dengan modal kecil, ia sukses mengubah nasibnya dan meraih kemenangan besar senilai 200 juta rupiah. Penasaran bagaimana caranya? Simak kisah lengkapnya di artikel tukang ojek online menang 200 juta dari Mahjong Ways 2.

UID_87427935###

Cek yuk! 🚍👮♂️Operasi Keselamatan 2025 Polres Ciamis Siapa tahu bus favoritmu jadi sasaran! 😱👍

UID_18563832###

Ini yang di ganti >>> Yuk, ketahui lebih lanjut tentang Syarat Gabung OECD dan Pentingnya Ratifikasi Konvensi Antisuap di sini! 🕵️♀️🔎📚.

UID_83003169###

Kenalan yuk! 🤝 Dengan guru inspiratif ini, Guru Dede Sulaeman yang mengajarkan cara merapikan pakaian di kelasnya. 👕👚🎓

UID_97211224###

Yuk, sehat bersama! 👨⚕️👩⚕️ Cek kondisi tubuh kamu di Program Cek Kesehatan Gratis sekarang juga! 💉🌡️ Selalu jaga kesehatan, ya! 🏥💖

UID_72356120###

strong>Dari Ojek ke Sultan, Kisah Arman yang Mendadak Kaya – Hidup Arman berubah drastis setelah keberuntungan menghampirinya. Dari seorang tukang ojek, kini ia menikmati kehidupan mewah setelah memenangkan 300 juta di Dragon Fortune. Simak kisah inspiratifnya

Hiya, I’m really glad I’ve found this info. Nowadays bloggers publish just about gossips and web and this is actually frustrating. A good website with exciting content, that is what I need. Thanks for keeping this web-site, I will be visiting it. Do you do newsletters? Cant find it.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

продать аккаунт платформа для покупки аккаунтов

безопасная сделка аккаунтов продажа аккаунтов соцсетей

безопасная сделка аккаунтов купить аккаунт с прокачкой

продажа аккаунтов соцсетей перепродажа аккаунтов

продажа аккаунтов соцсетей биржа аккаунтов

безопасная сделка аккаунтов https://kupit-akkaunt-top.ru/

продажа аккаунтов профиль с подписчиками

Sell accounts Website for Selling Accounts

Online Account Store Verified Accounts for Sale

Ready-Made Accounts for Sale Buy accounts

Sell accounts Accounts market

Account trading platform Account Trading

Secure Account Purchasing Platform Accounts marketplace

Buy Pre-made Account Account market

Account Selling Service Purchase Ready-Made Accounts

Account Buying Service Account Store

Purchase Ready-Made Accounts Account Store

profitable account sales social media account marketplace

account trading platform account purchase

account purchase profitable account sales

account market account market

buy pre-made account accounts marketplace

website for buying accounts profitable account sales

account selling platform buy account

buy accounts account selling platform

online account store sell accounts

account acquisition purchase ready-made accounts

website for selling accounts account trading service

guaranteed accounts secure account purchasing platform

sell accounts website for buying accounts

account selling service account purchase

marketplace for ready-made accounts account store

find accounts for sale sell account

account selling platform guaranteed accounts

accounts marketplace verified accounts for sale

accounts market account sale

account trading service buy and sell accounts

account sale website for buying accounts

verified accounts for sale accounts for sale

account catalog account store

buy and sell accounts sell account

account acquisition account catalog

buy pre-made account account market

website for selling accounts https://accounts-offer.org

buy and sell accounts https://accounts-marketplace.xyz/

account buying platform https://social-accounts-marketplaces.live

verified accounts for sale https://accounts-marketplace.live/

account trading platform https://social-accounts-marketplace.xyz

ready-made accounts for sale accounts marketplace

buy accounts https://buy-accounts-shop.pro

social media account marketplace https://buy-accounts.live

account purchase https://accounts-marketplace.online

buy accounts https://social-accounts-marketplace.live

profitable account sales https://accounts-marketplace-best.pro

маркетплейс аккаунтов купить аккаунт

маркетплейс аккаунтов соцсетей магазины аккаунтов

биржа аккаунтов купить аккаунт

продажа аккаунтов akkaunt-magazin.online

биржа аккаунтов https://akkaunty-market.live

продажа аккаунтов kupit-akkaunty-market.xyz

продажа аккаунтов https://akkaunty-optom.live

биржа аккаунтов https://online-akkaunty-magazin.xyz/

маркетплейс аккаунтов https://akkaunty-dlya-prodazhi.pro

биржа аккаунтов https://kupit-akkaunt.online

buy aged fb account https://buy-adsaccounts.work

buy facebook accounts for advertising cheap facebook account

buy facebook advertising accounts https://buy-ad-account.top

buy aged facebook ads account https://buy-ads-account.click/

buying fb accounts https://ad-account-buy.top

buy aged facebook ads accounts buy facebook old accounts

buy facebook ads accounts https://ad-account-for-sale.top

buying facebook account https://buy-ad-account.click

buy old facebook account for ads https://ad-accounts-for-sale.work

buy google ads https://buy-ads-account.top

buy verified google ads account https://buy-ads-accounts.click

facebook ads accounts https://buy-accounts.click

buy google ad account https://ads-account-for-sale.top

buy google ads accounts https://ads-account-buy.work/

google ads agency accounts https://buy-ads-invoice-account.top

buy google ads invoice account https://buy-account-ads.work

buy google ads invoice account buy google ads invoice account

buy google ad threshold account https://sell-ads-account.click

buy google ads https://ads-agency-account-buy.click

facebook bm for sale buy facebook verified business account

buy google ads threshold account https://buy-verified-ads-account.work

buy facebook bm account verified bm for sale

facebook bm for sale https://buy-verified-business-manager-account.org/

buy business manager account https://buy-verified-business-manager.org/

buy facebook bm buy-business-manager-acc.org

buy verified facebook business manager account business-manager-for-sale.org

facebook business manager for sale https://buy-business-manager-verified.org

business manager for sale buy-bm.org

buy verified bm facebook https://verified-business-manager-for-sale.org

facebook bm buy buy-business-manager-accounts.org

tiktok ads account for sale https://buy-tiktok-ads-account.org

tiktok agency account for sale https://tiktok-ads-account-buy.org

buy tiktok ads https://tiktok-ads-account-for-sale.org

tiktok ads agency account https://tiktok-agency-account-for-sale.org

tiktok ads account buy https://buy-tiktok-ad-account.org

buy tiktok business account https://buy-tiktok-ads-accounts.org

tiktok ads account buy https://tiktok-ads-agency-account.org

buy tiktok ad account https://buy-tiktok-business-account.org

buy tiktok business account https://buy-tiktok-ads.org

Your article helped me a lot, is there any more related content? Thanks!

Keep up the wonderful piece of work, I read few content on this website and I believe that your weblog is really interesting and holds circles of superb information.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

https://semaglupharm.com/# Semaglu Pharm

is there generic for crestor: CrestorPharm – Crestor Pharm

https://semaglupharm.com/# Semaglu Pharm

is lipitor an ace inhibitor: USA-based pharmacy Lipitor delivery – LipiPharm

can crestor cause pancreatitis [url=https://crestorpharm.shop/#]rosuvastatin muscle twitching[/url] Crestor Pharm

http://crestorpharm.com/# Crestor Pharm

https://semaglupharm.shop/# SemagluPharm

Rybelsus for blood sugar control: Where to buy Semaglutide legally – Semaglu Pharm

crestor and plavix: Rosuvastatin tablets without doctor approval – CrestorPharm

CrestorPharm [url=https://crestorpharm.com/#]Best price for Crestor online USA[/url] п»їBuy Crestor without prescription

https://semaglupharm.shop/# Rybelsus for blood sugar control

Safe delivery in the US: No prescription diabetes meds online – how much bacteriostatic water to mix with 5mg of semaglutide

PredniPharm: prednisone 60 mg tablet – prednisone 40 mg

CrestorPharm [url=https://crestorpharm.shop/#]Crestor Pharm[/url] CrestorPharm

https://semaglupharm.shop/# semaglutide cheap

http://crestorpharm.com/# Crestor home delivery USA

CrestorPharm: can i take vitamin d with rosuvastatin – what foods should be avoided when taking rosuvastatin?

steroids prednisone for sale: brand prednisone – best pharmacy prednisone

http://semaglupharm.com/# rybelsus 14 mg buy online

FDA-approved Rybelsus alternative [url=http://semaglupharm.com/#]SemagluPharm[/url] SemagluPharm

prednisone prices: prednisone 10 mg canada – 50mg prednisone tablet

rybelsus savings: SemagluPharm – Affordable Rybelsus price

https://semaglupharm.shop/# SemagluPharm

Predni Pharm [url=https://prednipharm.shop/#]buy generic prednisone online[/url] PredniPharm

http://lipipharm.com/# Generic Lipitor fast delivery

side effects of crestor 5mg: Rosuvastatin tablets without doctor approval – Crestor Pharm

Lipi Pharm: can you stop taking atorvastatin – can i take bergamot with atorvastatin

https://semaglupharm.shop/# semaglutide compound side effects

buy prednisone 10mg online [url=https://prednipharm.shop/#]PredniPharm[/url] Predni Pharm

CrestorPharm: Crestor Pharm – Crestor Pharm

https://semaglupharm.com/# SemagluPharm

LipiPharm: LipiPharm – No RX Lipitor online

Crestor Pharm [url=http://crestorpharm.com/#]CrestorPharm[/url] Crestor Pharm

https://prednipharm.com/# drug prices prednisone

https://semaglupharm.com/# semaglutide allergic reaction

vicodin lipitor two percocet: atorvastatin generic for lipitor – Affordable Lipitor alternatives USA

side affects of crestor [url=https://crestorpharm.com/#]Crestor Pharm[/url] CrestorPharm

https://semaglupharm.com/# does rybelsus cause depression

Order Rybelsus discreetly: Semaglu Pharm – does rybelsus cause heartburn

CrestorPharm: No doctor visit required statins – Over-the-counter Crestor USA

rybelsus 50mg [url=http://semaglupharm.com/#]SemagluPharm[/url] rybelsus pill picture

https://semaglupharm.com/# Semaglu Pharm

Lipi Pharm: Lipi Pharm – LipiPharm

https://prednipharm.shop/# average cost of prednisone 20 mg

Predni Pharm: PredniPharm – Predni Pharm

can you stop lipitor cold turkey [url=https://lipipharm.shop/#]LipiPharm[/url] Online statin drugs no doctor visit

https://semaglupharm.com/# Semaglu Pharm

п»їBuy Lipitor without prescription USA: Online statin drugs no doctor visit – Lipi Pharm

Semaglu Pharm: SemagluPharm – Semaglu Pharm

online order prednisone 10mg [url=https://prednipharm.com/#]prednisone cost canada[/url] prednisone acetate

https://semaglupharm.com/# SemagluPharm

how long does it take to get rosuvastatin out of your system: Crestor Pharm – CrestorPharm

Predni Pharm: PredniPharm – prednisone 54899

https://prednipharm.shop/# prednisone 20 mg

LipiPharm [url=https://lipipharm.shop/#]LipiPharm[/url] LipiPharm

http://semaglupharm.com/# Semaglu Pharm

safe canadian pharmacy: ordering drugs from canada – canadian pharmacies online

canada pharmacy world: global pharmacy canada – canada drugs online reviews

http://canadapharmglobal.com/# canadian online pharmacy

India Pharm Global [url=https://indiapharmglobal.com/#]india online pharmacy[/url] top 10 pharmacies in india

canadian pharmacy online store: Canada Pharm Global – canadian discount pharmacy

purple pharmacy mexico price list: Meds From Mexico – Meds From Mexico

http://canadapharmglobal.com/# safe canadian pharmacy

https://medsfrommexico.com/# Meds From Mexico

buy canadian drugs [url=https://canadapharmglobal.com/#]canadian pharmacy no scripts[/url] canadian pharmacy store

online shopping pharmacy india: best india pharmacy – India Pharm Global

https://medsfrommexico.shop/# Meds From Mexico

http://canadapharmglobal.com/# canadian pharmacy scam

Meds From Mexico: mexico drug stores pharmacies – Meds From Mexico

canadian pharmacies that deliver to the us [url=http://canadapharmglobal.com/#]best mail order pharmacy canada[/url] canadian discount pharmacy

online shopping pharmacy india: India Pharm Global – indian pharmacies safe

http://indiapharmglobal.com/# mail order pharmacy india

Meds From Mexico: mexican border pharmacies shipping to usa – mexican online pharmacies prescription drugs

UID_92113907###

test

canada drugs online [url=http://canadapharmglobal.com/#]Canada Pharm Global[/url] legal to buy prescription drugs from canada

https://medsfrommexico.shop/# pharmacies in mexico that ship to usa

mexican mail order pharmacies: mexican pharmaceuticals online – Meds From Mexico

https://medsfrommexico.shop/# pharmacies in mexico that ship to usa

buy prescription drugs from canada cheap: pharmacy canadian superstore – canadian pharmacies comparison

http://canadapharmglobal.com/# canadian pharmacy price checker

canadian pharmacy victoza [url=https://canadapharmglobal.shop/#]best canadian pharmacy to order from[/url] 77 canadian pharmacy

India Pharm Global: online shopping pharmacy india – top 10 pharmacies in india

top 10 pharmacies in india: India Pharm Global – India Pharm Global

https://raskapotek.shop/# jobb på apotek

EFarmaciaIt [url=https://efarmaciait.com/#]ml gr[/url] EFarmaciaIt

askorbinsyre pulver apotek: flГҐtthalsbГҐnd hund apotek – Rask Apotek

http://svenskapharma.com/# Svenska Pharma

shop apotheke spanien: Papa Farma – Papa Farma

https://svenskapharma.shop/# Svenska Pharma

pillola zoely recensioni [url=https://efarmaciait.com/#]EFarmaciaIt[/url] farmacia on line piГ№ economica

Papa Farma: Papa Farma – Papa Farma

http://raskapotek.com/# Rask Apotek

Svenska Pharma: avmaskning hГ¤st receptfritt – Svenska Pharma

https://papafarma.com/# droguerГa productos

Rask Apotek [url=http://raskapotek.com/#]Rask Apotek[/url] apotek næringsdrikk

Rask Apotek: fotrulle apotek – vannrensetabletter apotek

https://efarmaciait.shop/# EFarmaciaIt

EFarmaciaIt: 50 mg in ml – EFarmaciaIt

Svenska Pharma [url=http://svenskapharma.com/#]Svenska Pharma[/url] Svenska Pharma

Rask Apotek: fotkrem apotek – kaliumnitrat apotek

http://efarmaciait.com/# EFarmaciaIt

http://efarmaciait.com/# EFarmaciaIt

Papa Farma: Papa Farma – meritene fuerza y vitalidad

askorbinsyre apotek [url=http://raskapotek.com/#]ansiktsmaske apotek[/url] aotek

https://raskapotek.shop/# Rask Apotek

brekningsmiddel apotek: Rask Apotek – Rask Apotek

apotek legevakt: Rask Apotek – Rask Apotek

quanto costa enterogermina [url=https://efarmaciait.shop/#]EFarmaciaIt[/url] costo augmentin

http://efarmaciait.com/# EFarmaciaIt

https://svenskapharma.com/# beställa recept apotek

movicol precio sin receta: Papa Farma – Papa Farma

parafarmacia barata: Papa Farma – Papa Farma

Svenska Pharma [url=https://svenskapharma.shop/#]apotek hem[/url] se recept apotek

http://efarmaciait.com/# EFarmaciaIt

Rask Apotek: tannfylling apotek – aktivt kull apotek

Svenska Pharma: Svenska Pharma – Svenska Pharma

opiniones de snack 55 [url=https://papafarma.shop/#]Papa Farma[/url] Papa Farma

https://efarmaciait.com/# EFarmaciaIt

https://raskapotek.shop/# betakaroten apotek

nicetile bustine: sirdalud 2 mg compresse – EFarmaciaIt

farmacias top telefono: 10 productos de parafarmacia – cepillo electrico oral b io 7

https://raskapotek.shop/# Rask Apotek

flukonazol apotek [url=https://raskapotek.com/#]beroligende til katt apotek[/url] Rask Apotek

Svenska Pharma: glidmedel apotek – Svenska Pharma

https://svenskapharma.com/# apotrk

desamix effe crema a che serve: EFarmaciaIt – EFarmaciaIt

niacinamide krem apotek [url=https://raskapotek.com/#]Гёyekatarr apotek[/url] oksygenmГҐler apotek

http://efarmaciait.com/# EFarmaciaIt

EFarmaciaIt: deursil 150 prezzo – cingal amazon

http://svenskapharma.com/# Svenska Pharma

Rask Apotek: propylenglykol apotek – myggspray apotek

Svenska Pharma [url=https://svenskapharma.com/#]Svenska Pharma[/url] Svenska Pharma

https://svenskapharma.com/# Svenska Pharma

Rask Apotek: Rask Apotek – Rask Apotek

apotek fraktfritt [url=https://svenskapharma.shop/#]apotek Г¶ppetider[/url] Svenska Pharma

http://svenskapharma.com/# Svenska Pharma

EFarmaciaIt: EFarmaciaIt – EFarmaciaIt

apotheek aan huis [url=https://medicijnpunt.shop/#]mijn medicijn bestellen[/url] online apotheek nederland

https://pharmaconfiance.com/# pharmcie de garde

apteka amsterdam: Medicijn Punt – recepta online

luitpoldapotheke: online apotheke versandkostenfrei auf rechnung – PharmaJetzt

https://pharmaconnectusa.com/# Pharma Connect USA

europaapotheek [url=https://pharmajetzt.shop/#]Pharma Jetzt[/url] apotheke versandapotheke

http://pharmaconfiance.com/# Pharma Confiance

online aptheke: shop apotheje – PharmaJetzt

Pharma Connect USA: publix pharmacy online ordering – PharmaConnectUSA

https://medicijnpunt.com/# Medicijn Punt

Pharma Connect USA [url=http://pharmaconnectusa.com/#]chloramphenicol pharmacy[/url] levitra pharmacy prices

Pharma Confiance: Pharma Confiance – Pharma Confiance

Medicijn Punt: medicijn online bestellen – medicijnen zonder recept

https://pharmajetzt.com/# PharmaJetzt

https://medicijnpunt.com/# Medicijn Punt

pharmacy online netherlands [url=https://medicijnpunt.com/#]MedicijnPunt[/url] MedicijnPunt

apotheke online bestellen: PharmaJetzt – internet apotheke selbitz

http://medicijnpunt.com/# Medicijn Punt

cialis sans ordonnance pharmacie france [url=https://pharmaconfiance.shop/#]Pharma Confiance[/url] Pharma Confiance

PharmaConnectUSA: Pharma Connect USA – asda pharmacy ventolin inhalers

http://pharmaconfiance.com/# Pharma Confiance

cantura akut 12 apotheke: versandapotheke bad steben – internetapotheke versandkostenfrei

http://pharmaconfiance.com/# Pharma Confiance

Pharma Confiance [url=https://pharmaconfiance.shop/#]Pharma Confiance[/url] Pharma Confiance

medikamente apotheke: pille danach online bestellen – internet apotheken

http://pharmajetzt.com/# PharmaJetzt

secure medical online pharmacy: economy pharmacy – PharmaConnectUSA

shop apotheke versandkostenfrei [url=https://pharmajetzt.shop/#]PharmaJetzt[/url] PharmaJetzt

gГјnstigste internetapotheke: Pharma Jetzt – online apotheke kostenloser versand

https://pharmaconnectusa.shop/# PharmaConnectUSA

Medicijn Punt: Medicijn Punt – MedicijnPunt

Pharma Connect USA: Pharma Connect USA – princeton u store pharmacy

https://medicijnpunt.shop/# medicijnen bestellen online

med apotheke [url=https://pharmajetzt.com/#]Pharma Jetzt[/url] Pharma Jetzt

https://medicijnpunt.com/# pharma apotheek

0nline apotheke: pillen kaufen – Pharma Jetzt

accutane 40 mg online pharmacy: Pharma Connect USA – PharmaConnectUSA

versand apotheke online [url=http://pharmajetzt.com/#]PharmaJetzt[/url] Pharma Jetzt

http://pharmajetzt.com/# PharmaJetzt

target pharmacy nexium: Pharma Connect USA – Pharma Connect USA

online ativan pharmacy: best online pharmacy – oxybutynin online pharmacy

https://pharmajetzt.shop/# Pharma Jetzt

Pharma Connect USA [url=https://pharmaconnectusa.com/#]PharmaConnectUSA[/url] PharmaConnectUSA

https://medicijnpunt.com/# medicijnen bestellen apotheek

Pharma Confiance: pharmacie porte d’espagne avis – parapharmacie commande en ligne

https://pharmaconfiance.com/# Pharma Confiance

PharmaJetzt: PharmaJetzt – PharmaJetzt

Pharma Confiance [url=https://pharmaconfiance.com/#]Pharma Confiance[/url] Pharma Confiance

apotheek nl online: online apotheke – Medicijn Punt

https://pharmajetzt.com/# Pharma Jetzt

viagra pharmacy thailand: finasteride inhouse pharmacy – PharmaConnectUSA

mes medicaments chez moi [url=http://pharmaconfiance.com/#]phie des drakkars[/url] parapharmacie pas cher paris

http://pharmajetzt.com/# Pharma Jetzt

https://pharmajetzt.shop/# online apotheke wegovy

PharmaConnectUSA: PharmaConnectUSA – Pharma Connect USA

luitpold apotheke bad steben bestellschein: apo apotheke online – versandapotheken

PharmaJetzt [url=https://pharmajetzt.shop/#]shop apotheke deutschland[/url] PharmaJetzt

http://pharmaconfiance.com/# test grossesse pharmacie

apotheek nederland: MedicijnPunt – Medicijn Punt

online apotheek nederland: MedicijnPunt – recepta online

Pharma Connect USA [url=https://pharmaconnectusa.shop/#]Pharma Connect USA[/url] PharmaConnectUSA

https://pharmaconnectusa.com/# diflucan target pharmacy

https://pharmaconnectusa.com/# PharmaConnectUSA

is pharmacy rx one legitimate: Pharma Connect USA – Pharma Connect USA

viagra 200 mg avis: sra pharmacie – Pharma Confiance

shopapotal [url=http://pharmajetzt.com/#]apotheken internet[/url] Pharma Jetzt

http://medicijnpunt.com/# wat is mijn apotheek

digitale apotheek: Medicijn Punt – Medicijn Punt

Pharma Connect USA: PharmaConnectUSA – pharmacy online levitra

online apotheke bad steben [url=https://pharmajetzt.com/#]Pharma Jetzt[/url] apothekenversand

https://pharmaconnectusa.com/# naltrexone indian pharmacy

Medicijn Punt: MedicijnPunt – MedicijnPunt

http://pharmajetzt.com/# Pharma Jetzt

medicijn bestellen apotheek [url=http://medicijnpunt.com/#]Medicijn Punt[/url] Medicijn Punt

https://medicijnpunt.com/# Medicijn Punt

Pharma Jetzt: PharmaJetzt – Pharma Jetzt

apteka den haag [url=https://medicijnpunt.com/#]apotheek winkel 24 review[/url] MedicijnPunt

http://pharmaconfiance.com/# extra grasse

apotheek webshop: apotheken – Medicijn Punt

http://pharmaconfiance.com/# Pharma Confiance

MedicijnPunt: netherlands online pharmacy – Medicijn Punt

Pharma Confiance [url=https://pharmaconfiance.shop/#]avis new pharma[/url] Pharma Confiance

https://pharmaconfiance.com/# sans culotte lourdes

MedicijnPunt: MedicijnPunt – Medicijn Punt

https://pharmaconnectusa.com/# PharmaConnectUSA

PharmaJetzt: PharmaJetzt – shopa

snel medicijnen bestellen [url=https://medicijnpunt.com/#]MedicijnPunt[/url] MedicijnPunt

apotheek kopen: onlineapotheek – Medicijn Punt

http://pharmaconfiance.com/# Pharma Confiance

https://pharmaconfiance.shop/# Pharma Confiance

PharmaJetzt [url=https://pharmajetzt.com/#]Pharma Jetzt[/url] PharmaJetzt

medicijnen apotheek: Medicijn Punt – Medicijn Punt

Pharma Jetzt: shp apotheke – versandapotheke

https://pharmaconfiance.shop/# Pharma Confiance

Pharma Confiance [url=https://pharmaconfiance.shop/#]Pharma Confiance[/url] arrГЄter la drogue du jour au lendemain

test de pdg: Pharma Confiance – prix tadalafil

Pharma Confiance: parapharmacie. – pharmacien officine

Pharma Jetzt: PharmaJetzt – Pharma Jetzt

https://pharmajetzt.com/# shop apptheke

https://medicijnpunt.com/# medicijnen op recept online bestellen

digitale apotheek [url=https://medicijnpunt.shop/#]MedicijnPunt[/url] MedicijnPunt

MedicijnPunt: medicijnen snel bestellen – Medicijn Punt

online apotheek frankrijk: Medicijn Punt – apotgeek

https://pharmaconnectusa.shop/# enalapril online pharmacy

shop aphotheke: Pharma Jetzt – PharmaJetzt

apotheke nl [url=http://medicijnpunt.com/#]netherlands pharmacy online[/url] MedicijnPunt

welche online apotheke ist am gГјnstigsten: PharmaJetzt – Pharma Jetzt

http://medicijnpunt.com/# beste online apotheek

MedicijnPunt: MedicijnPunt – Medicijn Punt

https://medicijnpunt.com/# medicijnen op recept

online shop apotheke: PharmaJetzt – PharmaJetzt

Pharma Connect USA: PharmaConnectUSA – cheap pharmacy cialis

apotheke shop online [url=http://pharmajetzt.com/#]PharmaJetzt[/url] PharmaJetzt

saxenda prix pharmacie prГЁs de marseille: muporicine – pharmacie du marchГ©

http://pharmaconnectusa.com/# pharmacy rx

Pharma Confiance: Pharma Confiance – avis slinda pilule

https://pharmaconnectusa.shop/# reliable online pharmacy accutane

onlineapotheek: apotheek online nederland – recept medicijn

PharmaConnectUSA [url=https://pharmaconnectusa.shop/#]cialis viagra online pharmacy[/url] Kamagra Polo

Pharma Jetzt: PharmaJetzt – Pharma Jetzt

https://medicijnpunt.com/# Medicijn Punt

les pharmacies: Pharma Confiance – nutri prescription paris

fiГЁvre chien traitement naturel: pharmarcie en ligne – Pharma Confiance

https://pharmaconnectusa.com/# PharmaConnectUSA

gГјnstig online apotheke [url=https://pharmajetzt.shop/#]apotheke germany[/url] liefer apotheke

https://pharmaconnectusa.shop/# lorazepam fearpharmacy

Pharma Confiance: qu’est-ce que ketoprofene 100 mg – pharmacie de paris nice

PharmaConnectUSA: Pharma Connect USA – online pharmacy accutane no prescription

medicijn online bestellen: MedicijnPunt – Medicijn Punt

http://pharmaconfiance.com/# pilule slinda

dutch apotheek: apotheek recept – MedicijnPunt

mijn apotheek [url=https://medicijnpunt.com/#]medicijnen aanvragen[/url] MedicijnPunt

viagra online pharmacy review: PharmaConnectUSA – topamax prices pharmacy

Pharma Confiance: commande viagra cialis – Pharma Confiance

https://pharmajetzt.shop/# PharmaJetzt

https://pharmaconnectusa.com/# pharmacy rx one reviews

target pharmacy lipitor [url=https://pharmaconnectusa.shop/#]advair mexican pharmacy[/url] Pharma Connect USA

MedicijnPunt: mijn apotheek online – Medicijn Punt

https://pharmajetzt.shop/# Pharma Jetzt

PharmaJetzt: Pharma Jetzt – PharmaJetzt

de apotheek: MedicijnPunt – Medicijn Punt

PharmaConnectUSA [url=http://pharmaconnectusa.com/#]buying online pharmacy[/url] target pharmacy viagra

prix fucidine: cialis prix france – caudalie anti tache avis

https://medicijnpunt.shop/# de apotheker

http://pharmaconnectusa.com/# orlistat generics pharmacy

medicijnen kopen: MedicijnPunt – apteka nl online

internet apotheke bad steben: apotheken – Pharma Jetzt

online pharmacy lorazepam: Pharma Connect USA – provigil internet pharmacy

PharmaConnectUSA [url=http://pharmaconnectusa.com/#]good online pharmacy[/url] PharmaConnectUSA

https://medicijnpunt.com/# bestellen medicijnen

medikamente aus holland online bestellen: apotal online – apotheke online bestellen

kaiser pharmacy: PharmaConnectUSA – Pharma Connect USA

https://medicijnpunt.com/# apteka nl online

п»їlegitimate online pharmacies india [url=https://indimedsdirect.com/#]indian pharmacy[/url] indianpharmacy com

https://tijuanameds.com/# best mexican online pharmacies

TijuanaMeds: TijuanaMeds – TijuanaMeds

certified canadian pharmacy: canadian pharmacy meds reviews – canada cloud pharmacy

This web site is really a stroll-by way of for all the info you wished about this and didn’t know who to ask. Glimpse here, and you’ll undoubtedly uncover it.

https://indimedsdirect.com/# IndiMeds Direct

medicine in mexico pharmacies [url=http://tijuanameds.com/#]mexican drugstore online[/url] TijuanaMeds

canadian pharmacy drugs online: canadian family pharmacy – canadian pharmacy 24

http://tijuanameds.com/# TijuanaMeds

mexican pharmaceuticals online: mexico drug stores pharmacies – TijuanaMeds

https://indimedsdirect.com/# indian pharmacy

reputable canadian pharmacy: CanRx Direct – pharmacy wholesalers canada

IndiMeds Direct [url=https://indimedsdirect.shop/#]IndiMeds Direct[/url] IndiMeds Direct

http://canrxdirect.com/# canada pharmacy 24h

TijuanaMeds: reputable mexican pharmacies online – TijuanaMeds

canadian pharmacies that deliver to the us [url=https://canrxdirect.shop/#]CanRx Direct[/url] legitimate canadian online pharmacies

http://canrxdirect.com/# best canadian pharmacy

http://tijuanameds.com/# reputable mexican pharmacies online

TijuanaMeds: TijuanaMeds – TijuanaMeds

buy canadian drugs [url=https://canrxdirect.com/#]CanRx Direct[/url] reliable canadian pharmacy

https://canrxdirect.shop/# trusted canadian pharmacy

TijuanaMeds: purple pharmacy mexico price list – TijuanaMeds

IndiMeds Direct [url=http://indimedsdirect.com/#]indian pharmacy paypal[/url] IndiMeds Direct

http://indimedsdirect.com/# IndiMeds Direct

IndiMeds Direct: indian pharmacy paypal – IndiMeds Direct

https://indimedsdirect.shop/# buy prescription drugs from india

mexico pharmacies prescription drugs: mexico drug stores pharmacies – TijuanaMeds

northern pharmacy canada [url=https://canrxdirect.shop/#]CanRx Direct[/url] canadian pharmacies comparison

https://tijuanameds.shop/# pharmacies in mexico that ship to usa

canadian mail order pharmacy: CanRx Direct – canadian pharmacy ltd

buying from online mexican pharmacy: best online pharmacies in mexico – TijuanaMeds

TijuanaMeds [url=http://tijuanameds.com/#]mexican rx online[/url] medicine in mexico pharmacies