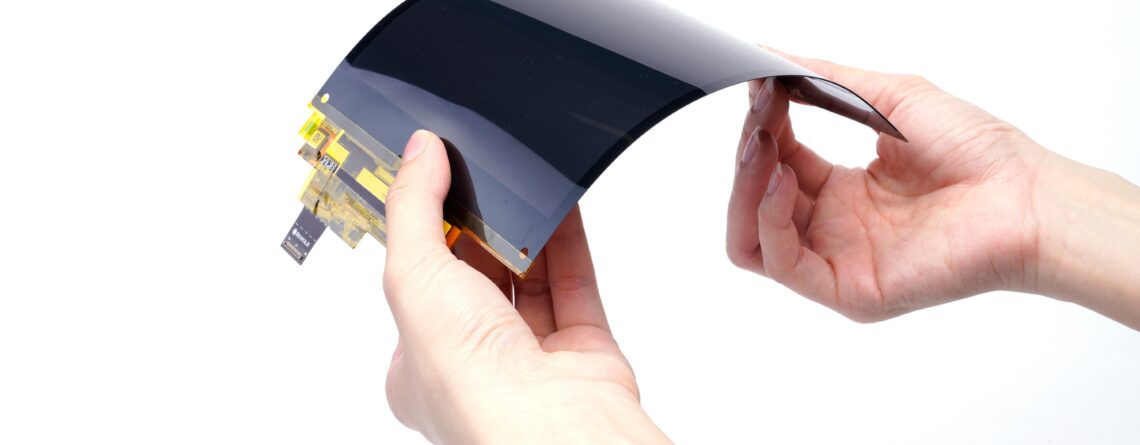

As the core interactive interface in manufacturing, energy, transportation and other fields, industrial displays have been facing harsh environments and high-intensity operation for a long time. Flexible screens with its bendable, lightweight, high adaptability characteristics, for industrial equipment, human-computer interaction to bring innovation opportunities, but also due to the radius of curvature caused by the touch precision problems encountered landing bottlenecks. How to ensure stable touch and accurate response of flexible screen under complex working conditions such as vibration, oil, extreme temperature, etc. has become the key to unlock the upgrade of industrial intelligence. In this paper, we analyze the logic and path of flexible screen adaptation in the industrial field from the technical challenges, core advantages and scene applications.

1. Conflict between precision and reliability in industrial scenarios

Industrial displays require the screen to maintain stable touch control under frequent bending, vibration and extreme temperature, which puts forward very high requirements on the physical resistance of the flexible screens. Screen bending, the conductive material of the touch layer due to stretching micro-cracks or resistance changes, resulting in signal attenuation or positioning drift; at the same time, the complex industrial environment, such as oil, electromagnetic interference, low temperature will further interfere with the touch sensitivity. In dynamic bending scenarios, the touch system needs to sense curvature changes and correct coordinate mapping in real time, which poses a double challenge to the hardware response speed and algorithm accuracy.

2. Industrial Adaptation Potential

The core advantage of flexible screens lies in the freedom of form and improved durability. It can be adapted to the surface of shaped devices to solve the installation limitations of traditional hard screens, such as adapting to the curved surface of robotic arms or folding screen devices in a narrow space; the use of highly malleable materials, such as metal mesh and graphene touch layer, significantly improves the life of the bends and meets the long-term use of industrial scenarios; combined with dynamic calibration algorithms, it can maintain the accuracy of the touch under different curvatures, and support complex operation modes such as gloves and wet hands, expanding the possibilities of industrial interaction. Expanding the possibility of industrial interaction.

3. Flexible Screens Application Fields

In automotive manufacturing, the flexible screen can be integrated into the curved panel at the joints of the robotic arm, displaying welding parameters in real time and supporting precise touch adjustment; in the energy field, the curled explosion-proof screen is used for inspection of oil pipelines in narrow spaces, and is resistant to extreme temperatures and vibrations; in the future smart factories, the flexible screens may be fused with AR technology, and become a flexible interactive terminal for the Industrial Internet of Things by switching between the equipment maintenance drawings and real-time data interfaces through bending and folding. Interactive terminal. This technology is reshaping the human-machine interface of industrial equipment, and promoting the evolution of manufacturing processes to high flexibility and intelligence.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com