Have you ever struggled to see your phone screen in bright sunlight? For outdoor displays, this challenge is even greater. Without proper treatment, screens under direct light produce strong glare, acting like a mirror and severely affecting visibility. How can this problem be solved? The answer lies in optical bonding technology. This technology is almost essential for outdoor displays—it is not an optional extra but a key feature for achieving high visibility outdoors.

Simply put, the main purpose of optical bonding is to minimize light reflection on the screen surface. This ensures excellent visibility even in bright conditions, such as direct sunlight.

This blog will explain in detail why outdoor displays use optical bonding, covering how it works, its benefits, and comparisons.

The Core Problem: Reflection—The Enemy of Outdoor Displays

Indoors, we mainly care about screen brightness. Outdoors, however, ambient light (especially sunlight) is much stronger than the light emitted by the screen. This causes two major problems:

① Surface Reflection: Like looking into a mirror, you see reflections of the sky, clouds, buildings, or yourself on the glass, making it hard to see the screen content.

② Internal Reflection: Even without mirror-like reflections, ambient light passes through the top glass and reflects between inner layers (like the touch sensor and LCD layer). This causes the screen to look washed out, with lower contrast and a grayish appearance.

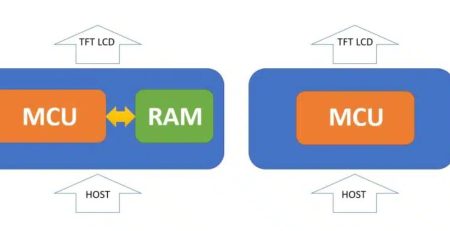

Traditional non-bonded displays (with an air gap) are like placing a clear glass in front of the screen. This makes both reflection effects much stronger.

How Does Optical Bonding Solve This?

Optical bonding uses an optical adhesive with a refractive index close to that of glass. It fully bonds the cover glass, touch sensor (if applicable), and display panel without any gaps.

The key is to remove the air layer.

① How Reflection Works: When light passes between different materials (like glass → air → glass), it reflects and refracts at each interface due to differences in refractive index. Air has a very different refractive index (~1.0) than glass (~1.5), causing significant reflection.

② Role of the Optical Adhesive: The optical adhesive has a refractive index (~1.4–1.5) similar to glass. Replacing the air layer with this adhesive makes the transition between materials much smoother. This greatly reduces internal reflection.

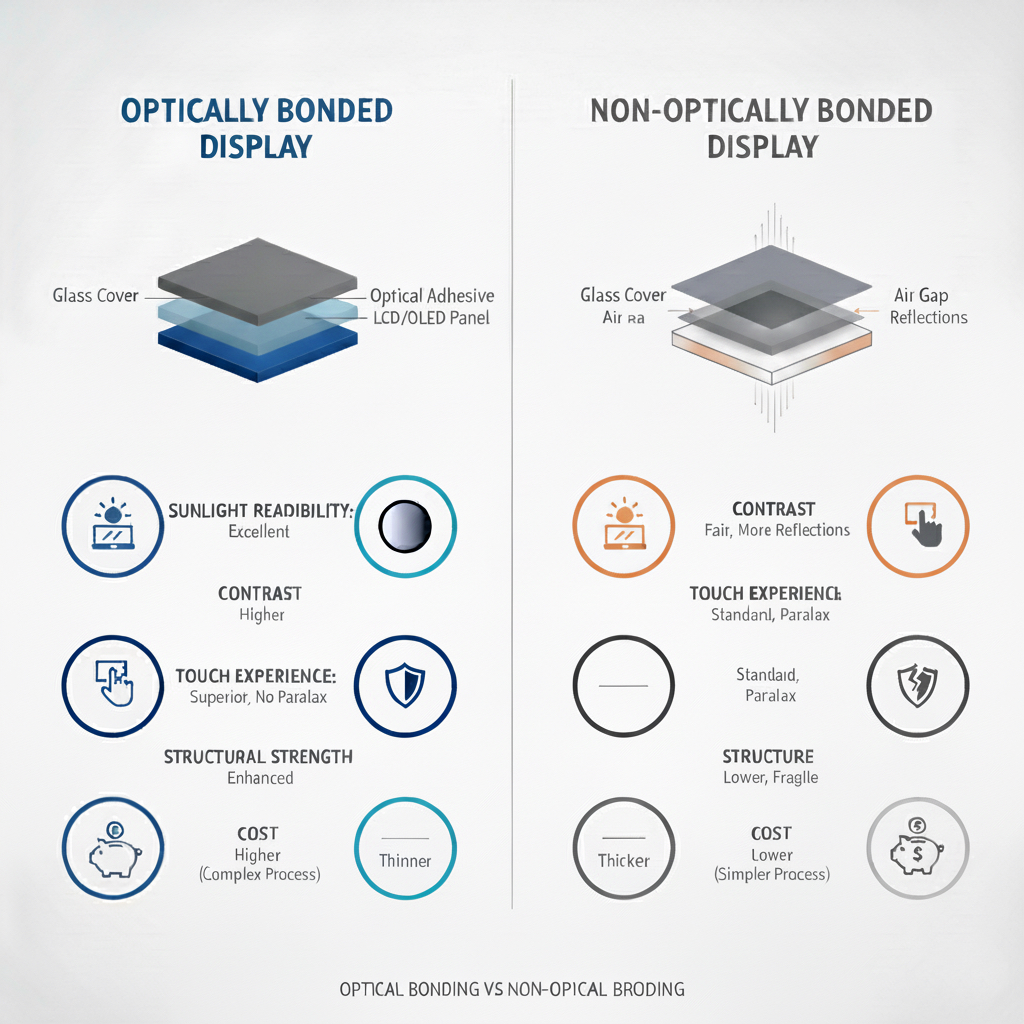

Major Benefits of Optical Bonding for Outdoor Screen

① Strong Anti-Reflection and Sunlight Readability

This is the biggest advantage. By reducing most internal reflection, interference from ambient light is minimized. Light from the screen can reach the viewer’s eyes more directly. So even at noon under sunlight, content remains clear, with colors and contrast preserved.

② Higher Contrast

Less reflection means blacks appear darker and whites appear brighter. Without reflected light “washing out” the screen, images look purer and more vibrant. The viewing experience is far better than with non-bonded screens.

③ Better Touch Experience (for Touchscreens)

For outdoor touch displays, optical bonding reduces the distance between the glass surface and the display layers. This almost eliminates parallax—the gap between where the eye sees content and where the finger touches. Touch becomes more accurate and natural.

④ Improved Durability and Heat Resistance

The optical adhesive is a strong binder that bonds all layers into one solid unit. This makes the screen assembly more robust. It better resists shocks, vibrations, and prevents moisture or dust ingress. This is ideal for harsh outdoor conditions. Also, the adhesive conducts heat, helping to transfer internal heat to the outside. This improves cooling and extends display life.

⑤ Thinner Screens

Removing air gaps between layers allows the entire display module to be thinner. This makes it easier to integrate into various outdoor devices and frames.

Comparison: Optically Bonded Display vs Non-Optically Bonded Display

To achieve sunlight-readable performance, our outdoor high-brightness series uses full bonding:

Optical Bonding: The touchscreen and LCD module are optically bonded for more realistic images.

Adhesive: We use silicone-based Wacker adhesive from Germany. Even under high temperatures, the adhesive won’t turn yellow.

Temperature Range: Withstands harsh conditions (operating temperature: -40°C to 110°C).

Tailored Solutions: GoldenMargins Offers Full Customization

Touch and Frame: Adjusted based on needs.

Coatings and Backlight: Optimal combinations for best performance.

Certifications: Supported by CE, RoHS, 3C, and ISO certifications.

As a global high-quality supplier in optical bonding, GoldenMargins provides precise and efficient services. We deliver professional display solutions.

Summary

For outdoor displays, optical bonding tackles the core challenge of bright outdoor environments by eliminating harmful internal reflection. Although it increases manufacturing costs, the benefits are unmatched: excellent sunlight readability, higher contrast, better durability, and improved touch experience. It is a essential technology for outdoor display applications. Without optical bonding, outdoor displays are hardly usable during daytime, greatly reducing their value.

Think of it like applying a top-tier anti-glare, high-transparency film to a premium car’s window. It lets you see outside (the screen content) clearly day and night, without interference from reflections.

At GoldenMargins, we understand these technical differences deeply. We are committed to providing customized solutions that meet diverse needs. Whether you need displays for outdoor environments or other types of screens, our expertise ensures you get the best product for your specific application. Want to learn more? Need professional guidance to choose the ideal display for your project? GoldenMargins—we are here to offer expert technical support.