Among various optical devices, the most important thing is screen clarity. Good screen clarity can not only bring a good user experience to users, but also improve product quality. For this reason, an important technology is AR ( anti-reflective) coating. It is a coating applied to the surfaces of screens and other optical devices to reduce reflections and increase the transmission of light. By reducing reflections on surfaces, this coating can significantly improve visibility and clarity, reduce glare, and enhance displays. This coating is widely used on various optical devices such as glasses, camera lenses, computer monitors, smartphone screens, etc. It is also important in industrial displays.

AR (anti-reflective) coating is an effective technology with multiple benefits.

1. Reduce glare and reflection.

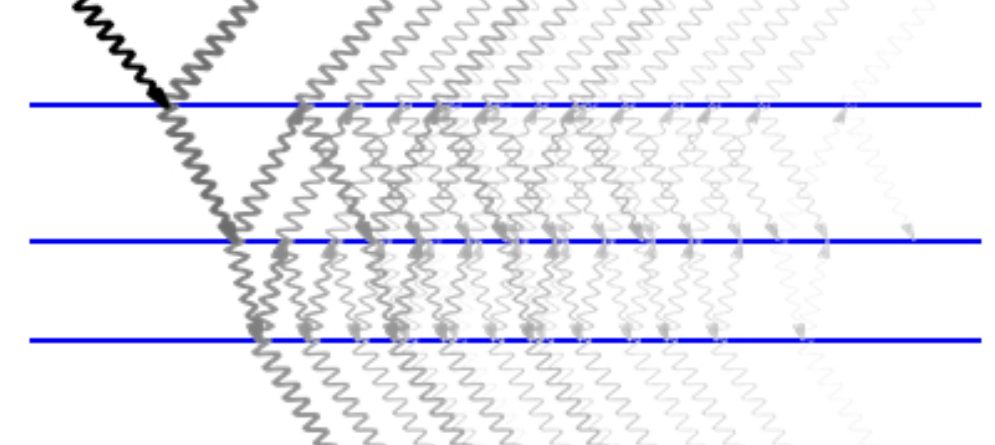

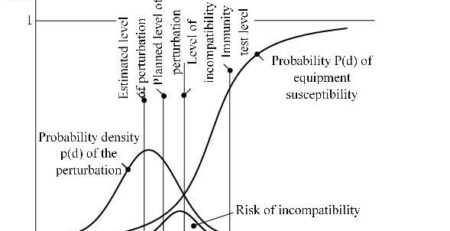

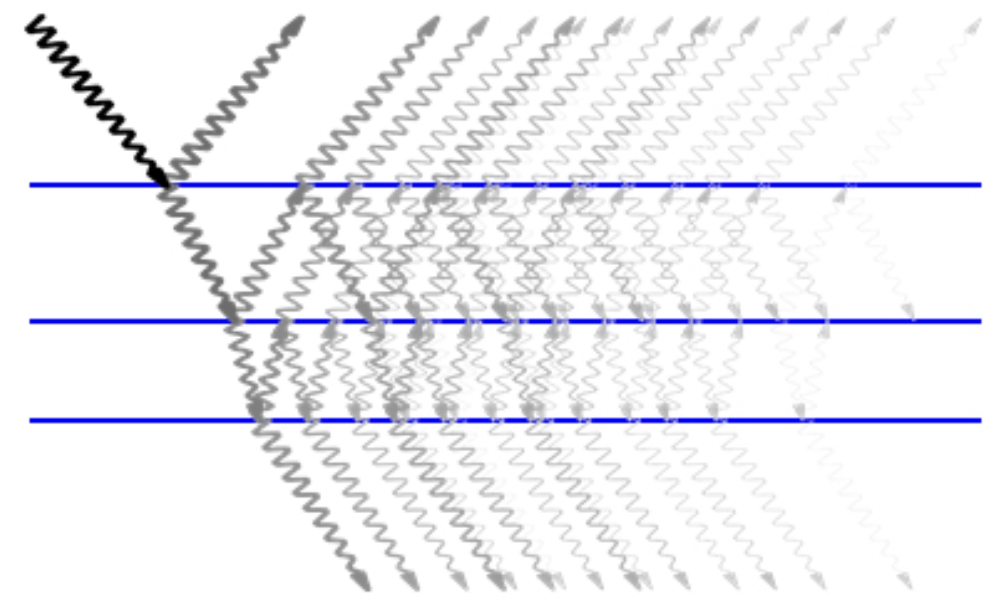

The principle is mainly the interference and refraction effect of light. Usually, anti-reflective coatings are designed with multi-layer films. By precisely designing the thickness and refractive index of each layer, light of different wavelengths occurs when light passes through different media (such as air, coating, and then glass). Interference cancels out part of the reflected light. As a result, only a small amount of light is reflected back and most of the light passes through the coating into the target device, reducing reflections and glare.

2. Reduce visual fatigue

Due to the multi-layer film coating, the anti-reflective ability is enhanced, effectively reducing glare caused by light reflection. This kind of glare can cause irritation to the eyes, causing the eyes to work hard to adjust to changes in light, leading to visual fatigue. By reducing glare, anti-reflective coatings improve the clarity of displayed content, enhancing image contrast and brightness. A clearer image means the eyes don’t need to focus or adjust too much, which reduces the burden on the eyes, makes the eyes’ vision more stable, and reduces eye fatigue.

3. Enhance image quality

In the field of optical technology, anti-reflective coatings play a key role in improving performance. AG anti-glare reduces the reflection of external light on the glass surface. By treating the glass surface with a microscopically rough texture that scatters incident light and reduces reflections, thereby improving visibility, minimizing reflections and maximizing light transmission, the efficiency of optical elements is increased.

4. Improve equipment durability

Anti-reflective coatings usually also have certain anti-scratch properties, mainly due to the particularity of the coating material, so they can increase the durability of the device surface and reduce scratches and wear.

In summary, the role of antireflective coatings in different optical applications is both important and transformative. Whether it is improving visibility, improving image quality or improving the performance of industrial display screens. Anti-reflective coatings have proven to be valuable tools in the field of optics. Their ability to reduce reflections and maximize light transmission opens up new possibilities in optical technology, improving functionality and user experience.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com