In the field of industrial displays, there are usually two ways to deal with display screens and touch screens. The first type is frame bonding, which are cheap but have corresponding shortcomings. The second type is full lamination, which uses special technology and glue. The price is relatively high, but the display effect is good. Frame bonding and full lamination LCD touch screens are two different screen bonding methods:

Frame Bonding: Frame Bonding refers to pasting the LCD screen and the touch layer together with a certain amount of glue or tape to form a frame. This method leaves a gap at the edge of the screen to accommodate the glue or tape, resulting in a noticeable black border around the screen. This simple method uses double-sided tape to stick the touch screen and the four sides of the display. The middle of the two screens is empty, which will cause air to enter.

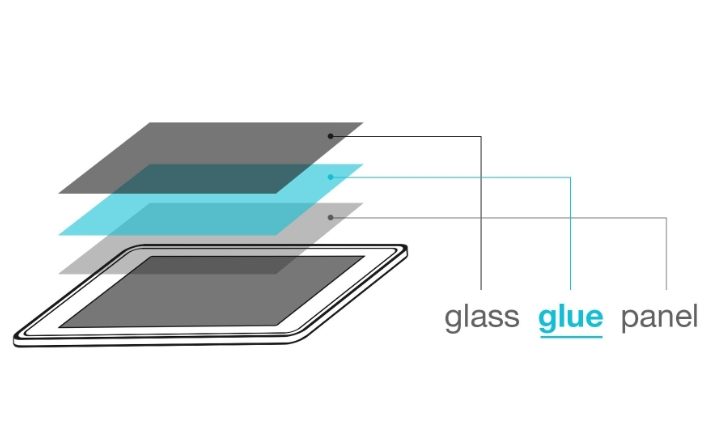

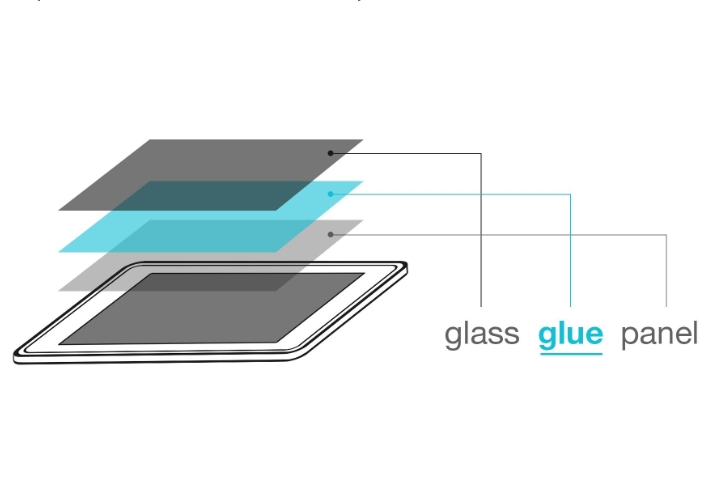

Full Lamination: Full lamination refers to processing the laminating materials such as LCD screen, touch layer and outer glass through special processes. Special water glue or transparent optical glue is usually used to make the touch screen and display screen seamless. Glue them together completely, like a piece of screen, so that they fit together perfectly. This method can eliminate the air between layers, improve touch sensitivity and display effects, and reduce light refraction to provide a better visual experience. Full lamination technology usually results in a thinner screen with no noticeable black bezel.

The different between frame bonding and full lamination LCD screens

1. Display effect: Full lamination technology eliminates the air between the screens, which can greatly reduce light reflection and reduce the loss of transmitted light, thereby increasing brightness and enhancing the display effect of the screen. The picture is clearer and more transparent, the contrast is improved, and the viewing experience is excellent. When the size of the frame bonding process is too large, the tempered glass will deform. When the deformation is too large, water ripples will appear on the surface of the LCD screen, affecting the user’s product experience.

2. Touch sensitivity: Full lamination LCD without air gaps can reduce delays and inaccuracies during touch, making the touch response faster and more accurate. Because there is a certain air gap between the layers of the frame bonding, because there is air between the two screens, it is easy to reflect light and dust may enter. In addition, the two screens are separated, and the light from the display screen will be filtered, resulting in poor visual effects. Touch sensitivity may be slightly lower, especially in brightly lit environments, and the touch response may not be as precise as full lamination technology.

3. Cost: The frame bonding technology has low cost and simple process. The frame is bonded with glue and is not easy to be damaged. Secondly, the maintenance cost is low, the two screens can be easily separated, and even if one is broken, it will not affect the use of the other. The fully laminated display panel is closely attached to the touch screen, effectively avoiding impurities such as dust and water vapor condensation. The process is complex, costly, and the cost of damage is high.

To sum up, the difference between frame bonding and full lamination LCD lies in the fitting method and effect. Frame bonding will have an obvious black border, while full lamination achieves better visual and touch effects without an obvious black border.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com