In industrial scenarios, displays are often exposed to dust, water, oil and other environments, and the necessary dust and waterproof measures can avoid these problems. Generally, IP67 protection can be dustproof, short-term water immersion can cope with most application needs. However, when it comes to corrosive environments such as strong acids and alkalis, relying on IP67 alone can lead to rapid equipment failure. For example, a display in the reaction area of a chemical plant may be sealed and deteriorated by exposure to sulfuric acid vapors, and the interface of a medical sterilization device may be shorted due to the penetration of hydrogen peroxide gas.

So what are the advantages and disadvantages of the IP67 standard in chemical environments?

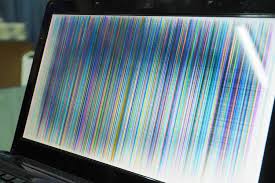

The IP67 rating ensures that equipment is protected for a certain period of time in dust or water, such as in water up to a depth of 1 meter and for up to 30 minutes, but it is not directly resistant to corrosion by strong acids or bases. Sometimes hydrochloric acid vapor may penetrate the plastic or metal seams of the display housing, resulting in seal deterioration, internal circuit short circuit. In addition, ordinary rubber seals are prone to swelling and failure when exposed to strong alkali, and metal housings are easily corroded by acid. Chemical media may gradually destroy the adhesive or solder joints at the interface, reducing the protection ability.

So how to improve ip67 protection level?

1. Material and process

IP67 displays can be adapted to mild chemical environments through material and process optimization. For example, the use of corrosion-resistant materials, the shell changed to polytetrafluoroethylene (PTFE) or glass fiber reinforced plastic, resistance to acid and alkali erosion. Seals can also be replaced with fluoroelastomer to resist liquids with pH 1-14, such as sulfuric acid and sodium hydroxide solutions.

2. Structural reinforcement

The interface is ultrasonically welded or laser sealed to avoid the glue being dissolved by chemical media. In addition, the screen surface is covered with chemically tempered glass to prevent damage from liquid splash.

ip67 application fields

Chemical production line. It is used for the control screen of the reaction kettle with acid and alkali concentration ≤5%, and the pipeline flow monitoring terminal. However, it is necessary to check the status of the seal regularly to avoid material fatigue caused by long-term exposure. Medical sterilization equipment, operation interface of hydrogen peroxide (H₂O₂) sterilization chambers, relying on Viton seals to prevent gas permeation. Laboratory Instruments. Sample analyzers with touch screens that need to withstand splashing of liquids with pH 3-11 use a combination of PTFE-coated and chemically tempered glass solutions.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com