Resistive touch screens are a popular and widely used type of touchscreen technology. They are found in a variety of devices, ranging from consumer electronics like smartphones and tablets to industrial equipment, public information displays, and point-of-sale systems. These touch screens offer an interactive interface that allows users to interact with the device by simply touching the screen.

Resistive Touch Screen Structure and Components

Layers and Components: Exploring the Anatomy of Resistive Touch Screens

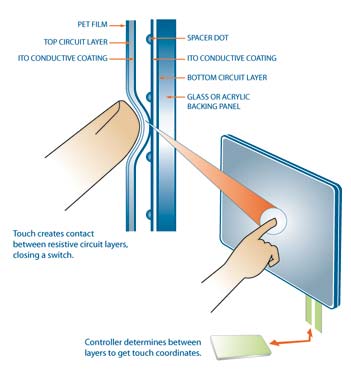

A resistive touch screen consists of several layers that work together to detect touch input accurately. The primary components of a resistive touch screen include two transparent layers: a flexible top layer and a rigid bottom layer. The top layer is typically made of polyester material, while the bottom layer is made of glass or rigid plastic material. Between these layers, there is a thin separator dot layer that keeps the top and bottom layers apart when the screen is not in use.

Working Principle of Resistive Touch Screens

Detecting Touch Input: Unveiling the Activation Process

The working principle of a resistive touch screen is based on the concept of pressure applied by the user’s touch. When pressure is exerted on the top layer of the screen, it comes into contact with the bottom layer, causing the layers to make physical contact at the precise touch point. This contact completes an electrical circuit, allowing the touch screen controller to detect the touch and determine its coordinates on the screen.

Resistive touch screens utilize a resistive film or layer on the bottom layer, which contains conductive material. When the top layer makes contact with the bottom layer, the conductive material creates a voltage drop at the touch point. The touch screen controller measures the voltage drop and calculates the touch position based on the change in electrical resistance.

Advantages of Resistive Touch Screens

Versatility in Input Methods

Resistive touch screens offer versatility in input methods. They can be operated with a finger, gloved hand, stylus, or any other object that applies pressure to the screen. This flexibility makes resistive touch screens suitable for various user preferences and environments.

Accurate Touch Point Detection

Resistive touch screens provide accurate touch point detection. They can detect multiple touch points simultaneously, enabling features like pinch-to-zoom and multi-finger gestures. The precise touch detection allows for accurate interaction with on-screen elements and enhances the overall user experience.

Compatibility with Various Environments

Resistive touch screens are compatible with various environments, including indoor and outdoor settings. They can withstand harsh conditions such as temperature variations, dust, and moisture. Some resistive touch screens are designed to be water-resistant and can be operated even with wet fingers or in rainy conditions.

Limitations of Resistive Touch Screens

Need for Direct Physical Pressure

One limitation of resistive touch screens is the need for direct physical pressure to register touch input. The user must press on the screen with sufficient force to create contact between the layers. This requirement can lead to fatigue when using the touch screen for extended periods.

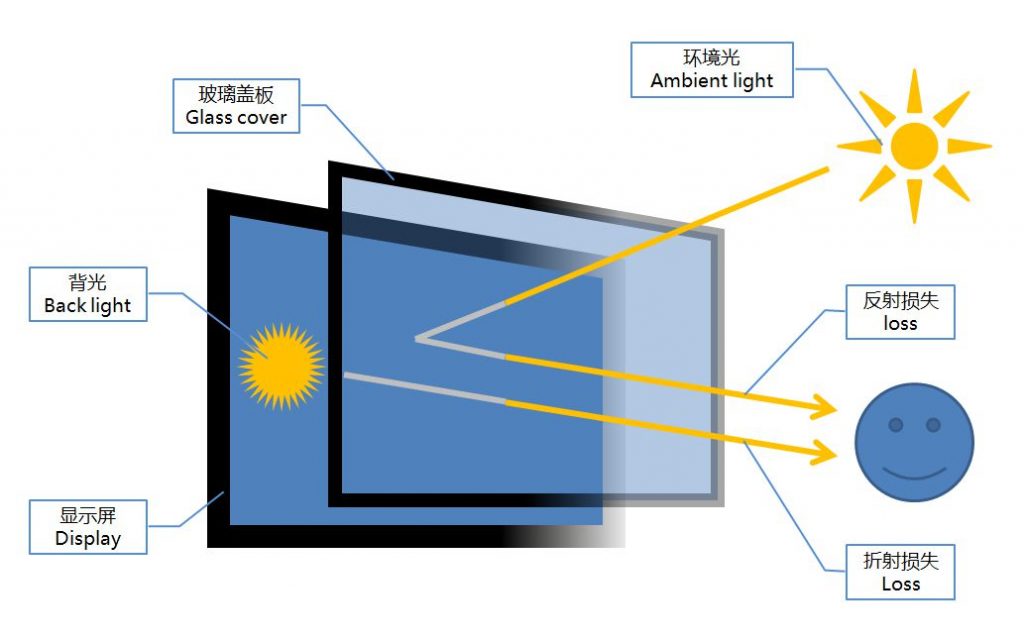

Potential Reduction in Display Clarity and Brightness

Resistive touch screens consist of multiple layers, which can affect the display clarity and brightness. The additional layers may cause a slight reduction in the overall visual quality compared to screens without touch functionality. However, advancements in technology have minimized this impact, and modern resistive touch screens offer improved display performance.

Periodic Recalibration Requirements

Resistive touch screens may require periodic recalibration to maintain optimal performance. Over time, factors such as temperature changes and prolonged use can affect the accuracy of touch detection. Recalibration helps realign the touch screen and ensures accurate touch input.

Conclusion

Resistive touch screens provide a reliable and versatile touch input solution for a wide range of applications. They offer accurate touch point detection, compatibility with various environments, and support for different input methods. While they have some limitations, such as the need for direct physical pressure and occasional recalibration, resistive touch screens continue to be a popular choice in many industries. With ongoing advancements in technology, resistive touch screens are expected to evolve further, offering enhanced performance and improved user experiences.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com

Comments (16)

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

UID_74743238###

Ini dia! 🎉🎉 ASN BKN Ubah Pola Kerja yang baru dan efisien! 🎉🎉.

UID_83344528###

Inilah 🎉🎉 Pupuk Inovatif Kebun Riset Kujang yang bikin Wamen BUMN bangga! 💪🏻🇮🇩

UID_25978847###

situs terbaik hanya di slot gacor agentotoplay

UID_95859078###

Baru-baru ini, para pemain Mahjong Wins 3 dikejutkan dengan bocoran RTP yang diklaim bisa meningkatkan peluang kemenangan secara signifikan. Banyak yang percaya bahwa informasi ini membantu mereka mendapatkan hasil yang lebih konsisten dalam permainan. Jika Anda ingin tahu lebih lanjut, cek bocoran RTP Mahjong Wins 3 hari ini dan lihat apakah strategi ini benar-benar efektif.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

UID_57331425###

Skandal terbaru mengguncang komunitas pecinta game slot setelah seorang admin terkenal, Rachel, dikabarkan tertangkap membocorkan pola kemenangan Gate of Olympus. Banyak yang bertanya-tanya apakah informasi ini benar-benar akurat atau hanya sekadar rumor yang beredar di kalangan pemain. Simak lebih lanjut detailnya dalam artikel admin Rachel tertangkap bocorkan pola Gate of Olympus.

UID_17136916###

Kisah inspiratif datang dari seorang tukang ojek online asal Tangerang yang berhasil membawa pulang hadiah fantastis setelah bermain Mahjong Ways 2. Dengan modal kecil, ia sukses mengubah nasibnya dan meraih kemenangan besar senilai 200 juta rupiah. Penasaran bagaimana caranya? Simak kisah lengkapnya di artikel tukang ojek online menang 200 juta dari Mahjong Ways 2.

UID_18563832###

Ini yang di ganti >>> Yuk, ketahui lebih lanjut tentang Syarat Gabung OECD dan Pentingnya Ratifikasi Konvensi Antisuap di sini! 🕵️♀️🔎📚.

UID_83003169###

Kenalan yuk! 🤝 Dengan guru inspiratif ini, Guru Dede Sulaeman yang mengajarkan cara merapikan pakaian di kelasnya. 👕👚🎓

UID_97211224###

Yuk, sehat bersama! 👨⚕️👩⚕️ Cek kondisi tubuh kamu di Program Cek Kesehatan Gratis sekarang juga! 💉🌡️ Selalu jaga kesehatan, ya! 🏥💖

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

UID_81474082###

test

Your article helped me a lot, is there any more related content? Thanks!