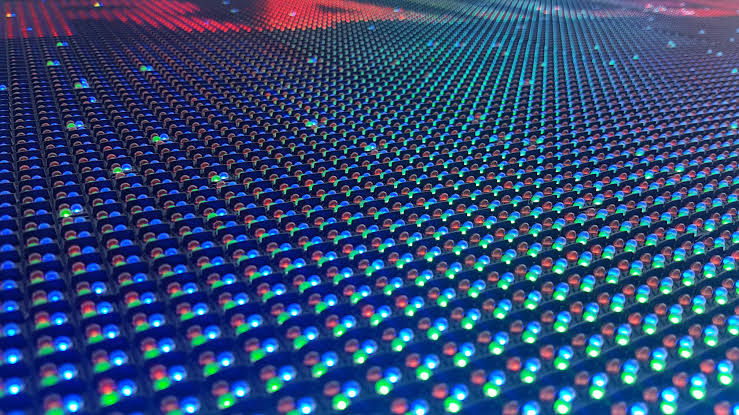

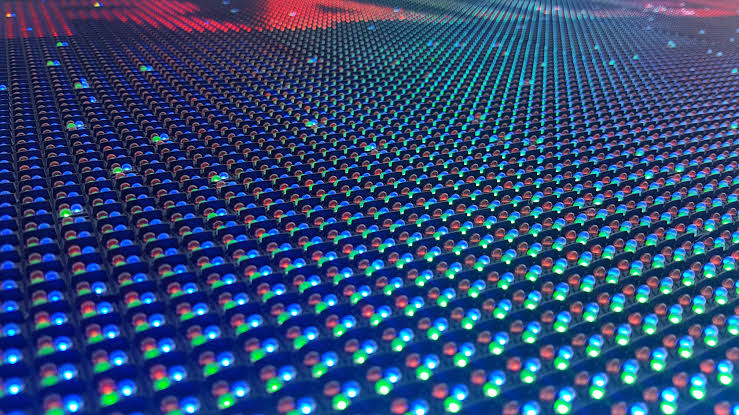

With the advancement of industrial display technology, modern industrial workshop on the quality of light and information visualization needs are becoming more and more stringent. In particular, precision manufacturing, warehousing and logistics scenarios require both stable operational lighting and real-time data monitoring to ensure production efficiency. Traditional solutions are usually deployed separately from the lighting system and electronic display, resulting in equipment redundancy, increased energy consumption, and in dusty, oily environments facing complex maintenance issues. The micro-pitch LED screen (pixel pitch ≤ 1.0mm) through technological innovation, not only realizes the physical integration of lighting and information display functions, but also its high-density light-emitting units not only provide uniform illumination of the work surface, but also dynamically display the production data, equipment status or operating instructions, thus simplifying the layout of the workshop infrastructure, improve the utilization of space and information interaction efficiency.

What are the advantages of micro pitch LED screen?

1. Dustproof and waterproof high heat dissipation

Macro-pitch LED screen in the workshop environment is the primary difficulty facing the heat dissipation and protection design. Workshop usually exists in high temperature, dust or oil environment and other issues, LED modules need to be sealed package (such as COB technology) to achieve IP65 protection level, to prevent oil and water. In addition, they have built-in efficient heat dissipation structures. For example, you can customize the aluminum heat dissipation bracket, which can control the temperature of the screen body below 50 ℃, to avoid overheating caused by brightness attenuation. Finally, installation and maintenance costs need to be optimized. With limited space and dense equipment in the workshop, the modular design allows for quick replacement of a single piece in case of damage, reducing downtime.

2. Multi-functionality and efficiency improvement

The core advantage of micro-pitch LED is dual-function integration. Traditional workshops need to install lighting fixtures and information screens, while the LED screen can simultaneously output 500-1500cd/m² of uniform illumination, and display production data on the same surface, and can display real-time information and equipment status. In addition, the dynamic adjustment ability is remarkable, through the programming can be partitioned to control the brightness compared to fixed lighting energy saving 30%.

Typical Application Scenarios

In semiconductor manufacturing plants, micropitch LEDs are used to monitor equipment status in clean rooms. With a pixel pitch of less than 1mm, they can clearly display wafer processing parameter charts and provide flicker-free illumination for precision operation tables. In addition, the wide color gamut characteristics of the LED screen, with different colors of light to distinguish the pipeline area, such as red for the high temperature zone, blue for the cooling zone, can effectively assist workers to quickly identify the work area.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com