In the field of industrial display and the wave of intelligent manufacturing, more and more scenes need to use to industrial display, complex scene demand is also more and more, such as high-temperature workshop, extreme cold oil field, medical operating room, outdoor display, intelligent logistics warehouse, etc., the customization service of the industrial display is becoming the key to improve the efficiency of the enterprise and reduce costs. The industrial display customization becomes more and more important.

Core modules of industrial display customization service

1. Hardware customization

Hardware parameter customization is the basic of industrial display customization, according to the application requirements can be customized with different resolutions (1080P to 8K) and display technologies (such as cost-effective LCD, high-contrast OLED), but also free to customize the size of the 7-55 inches, so as to meet the visual needs from a variety of display devices and outdoor construction machinery, while the industrial display also has IP65 to IP67 At the same time, the industrial display also has IP65 to IP67 dustproof and waterproof protection level and explosion-proof certification, which can ensure the stable operation of the equipment in the oil, humidity and even chemical explosion environment.

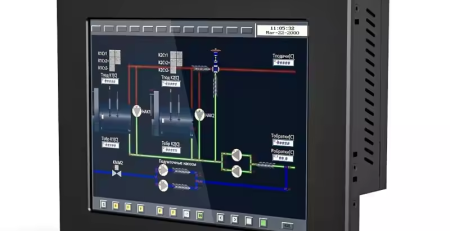

2. Interface and communication protocol customization

Interface is another major customization advantage of industrial monitors. Different interfaces can make the data connectivity of industrial scenarios become more flexible. For example, the integration of RS485, CAN bus and other industrial standard interfaces, compatible with Siemens, Mitsubishi and other mainstream PLC equipment. In addition, it can also extend 5G, Wi-Fi and other IoT modules to realize efficient interaction between devices and the cloud, and with the Ethernet interface, the real-time data refresh delay is compressed to less than 50 milliseconds, which makes it more flexible and efficient for high-speed production line control.

3. Customized environmental adaptability

The industrial display adopts wide-temperature LCD module and heating film technology, so that the screen can still start up quickly in temperatures ranging from -40℃ to 85℃. Through the impact-resistant structure and anti-glare optical design, the outdoor display content can also be clearly seen. In addition, industrial displays are also corrosion tested to ensure that the equipment can be used properly in humid and high salt scenarios.

4.Other customization

The development of software function depth breaks the interaction bottleneck of traditional HMI, and adapts to the globalized production demand through multi-language dynamic switching. Gesture operation and glove touch customization optimization, so that workers do not need to remove protective equipment to operate smoothly. Through remote operation customization, we can diagnose the system and achieve 48-hour fault response, and combine AR interactive tutorial customization with user habit data analysis to continuously optimize the equipment experience.

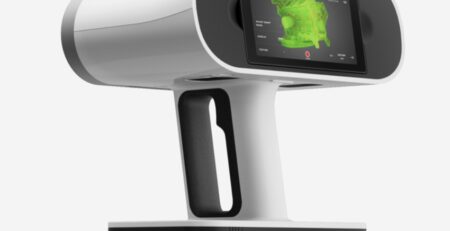

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com