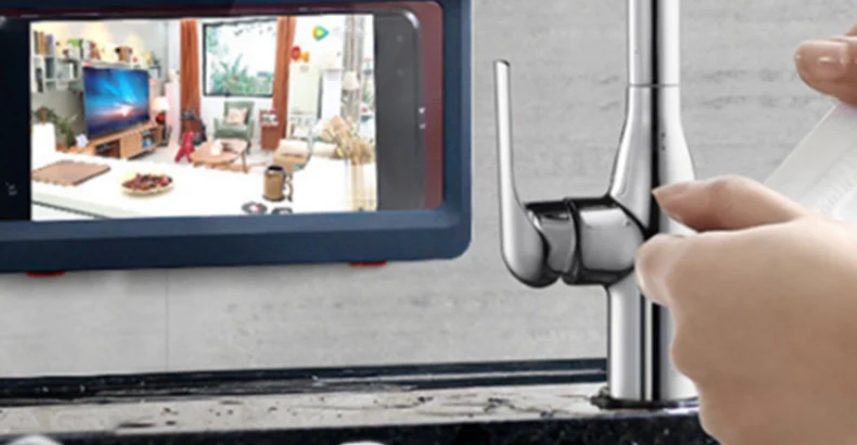

There are many application scenarios involving water or moisture in people’s lives, such as using electronic devices in rainy days, kitchens, bathrooms, swimming pools, or outdoor activities, etc. In order to enhance the convenience of people’s lives, the waterproofing of waterproof touchscreen has become increasingly important. The waterproof function not only greatly enhances the durability and reliability of the device, but also reduces the risk of damage caused by water contact.

In environments such as factories, manufacturing plants or laboratories, touch screen control devices will inevitably come into contact with liquids, dust, chemicals or humidity. Therefore, in order to prevent touch screen malfunctions due to liquid ingress or dust ingress into the device, and to ensure the stability and safety of the device, it is necessary to use a touch screen with a waterproof function.

So, even in contact with water or humid environment so that the device can still work properly, waterproof touchscreen to achieve waterproof function, we usually have to use what technology and design strategy?

1. Optical bonding technology

In the field of industrial-grade touch monitors, we usually use the Optical bonding technology. It will display panel and touch screen through a special optical adhesive tightly bonded together, not only to avoid the air layer in the traditional screen, eliminating air bubbles, preventing water vapour or dust from entering the device, enhanced waterproof, dustproof ability, but also to improve the display effect, is the sponge more realistic and vivid.

2. Waterproof material

Screen material waterproof design, waterproof touchscreen surface will usually use a reinforced glass or other waterproof material, this glass or material has a sealed, can effectively prevent moisture and dust into the internal circuitry to ensure the safety of electronic components. In addition, even if there are water drops or splashes on the surface of the touch screen, it will not affect people’s operation of the touch screen or the sensing function of the touch screen.

3. Hydrophobic Coating

In order to ensure foolproof, many waterproof touchscreen will be coated with a hydrophobic coating on the surface of the glass, the advantage of this coating is that the water droplets falling on the surface of the touch screen will form a bead, and will not spread on the screen, in addition, this coating will not allow the water droplets to interfere with the normal touch function of the screen, does not affect the normal operation of the user.

4. Waterproof design

In order to ensure the waterproof and dustproof function, and make sure the liquid can’t penetrate to the inside through the edge, a waterproof sealing process is usually used at the combination of the touch screen and the chassis. This sealing material can be rubber ring or waterproof adhesive, which can ensure the waterproof touchscreen performance of the device. In addition, in the circuit design of waterproof touchscreens, the parts of the circuit board and the touch control chip are usually treated with a waterproof coating to further prevent water from penetrating into the circuit board, leading to short circuits or damage to the device.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com