Under the wave of rapid industrial development, the display terminal has not only become a window for information interaction, but also an important part of industrial intelligence. With the increasing complexity of the production environment and application scenarios, a variety of industrial display devices functions also need to be constantly improved, in addition to resolution, brightness, response time and other conventional parameters, those “invisible” technical details are often the key to determine competitiveness.

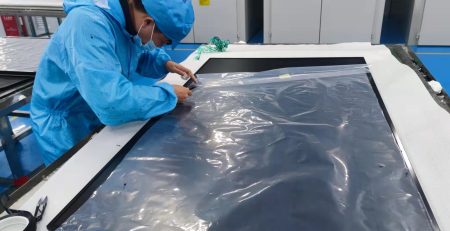

Reliability in extreme environments

Industrial site environment is complex and variable, temperature, humidity, dust, oil and other factors that may affect the stability of the display. In the steel, automobile manufacturing and other industries, due to its working environment is often in -30 ℃ to 80 ℃, so the extreme temperature is also required to monitor the normal operation. The traditional frame pasted screen in the temperature difference when the drastic changes, easy to condense and lead to fogging or even failure, and the use of fully laminated process of the industrial display devices not only can effectively prevent the entry of water vapor, but also improve the impact resistance and optical properties, even in extreme environments can ensure that the display effect is stable and reliable.

High Protection Grade

In a variety of production workshop scenarios, dust, oil, moisture, etc. in the workshop may damage common display devices. Therefore, IP67 grade dustproof and waterproof function has become one of the standard features of industrial displays. In some foundries, dust particles are very easy to enter the inside of the equipment, and water molecules can easily enter the inside of the display, leading to circuit short-circuiting or screen malfunction. Therefore, industrial display devices with IP67 certification level can ensure that the display can operate stably in dust-intensive environments, and even if it encounters water splashing or is briefly immersed, its performance will not be affected.

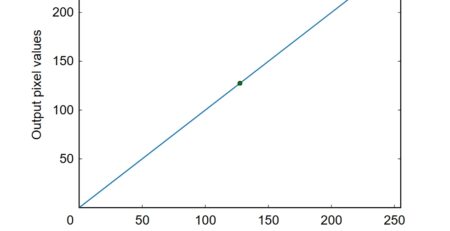

Visibility in bright light

When industrial monitors are used outdoors or in brightly lit shops, strong light and light reflections can seriously affect readability. The AG (anti-glare) coating effectively reduces the reflectivity of the screen surface so that the industrial display devices remain visible in bright light. Data shows that compared to ordinary glass screens, AG coating can increase visibility by 60%, significantly improving the operator’s experience.

Intelligent diagnosis and maintenance

Intelligence is an important trend in the development of industrial display devices. In the field of automobile manufacturing, display terminals with predictive maintenance function can be equipped on the production line, which can monitor the status of the equipment in real time and provide early warnings before failures occur, significantly reducing the risk of unplanned downtime. Data shows that the system has reduced production line downtime by 75%, significantly improving production efficiency. The application of this intelligent diagnostic technology makes the display not only an information output device, but also an important node for data collection and production management.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com