In industrial scenarios, displays often face harsh environments such as high temperatures above 70°C, high humidity, and strong vibration. Under such conditions, ordinary consumer-grade displays are prone to whitening of the screen, touch failure, and even glass cracking due to insufficient material performance; while industrial display need to operate stably for 3-5 years, and the core lies in the targeted optimization of the material system.

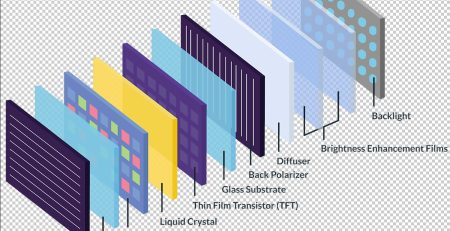

The glass substrate is the physical support and light-transmitting medium of the industrial display, and its performance directly affects the impact resistance and environmental adaptability. Traditional soda-lime glass is prone to “rainbow spots” or self-cracks due to internal stress imbalance under high temperature and high humidity environments due to the easy migration of alkali metal ions, and the bending strength is only about 50MPa, which is difficult to resist mechanical collision. Industrial-grade displays mostly use chemically strengthened glass (such as aluminosilicate glass), which forms a compressive stress layer on the surface through an ion exchange process, increasing the bending strength to 200-300MPa. At the same time, the thermal expansion coefficient is more matched with the LCD module, and it is not easy to peel off at high temperatures.

Another threat of high temperature and high humidity environments is internal corrosion caused by water vapor penetration. The circuit board, polarizer, and liquid crystal layer inside the industrial display are sensitive to moisture: water vapor will dissolve the PVA film of the polarizer, causing polarization failure, and will also corrode the solder joints of the circuit board and cause oxidation short circuits. Industrial-grade displays block water vapor through “triple protection”: the frame uses silicone rubber or fluororubber sealing rings, which can withstand temperatures of -50℃~200℃ and form a 0.1mm sealing gap; epoxy resin glue is filled between the display and the backlight module (the moisture permeability is less than 1g/(m²·day)); the glass surface is coated with a fluorocarbon coating to repel condensed water. A chemical equipment company’s actual measurement shows that after replacing this solution, the display has been running in a high-temperature and high-humidity workshop for 2 years without water vapor erosion.

As a “light regulator”, the core material PVA film of the polarizer has strong hygroscopicity and is easy to expand and degrade under high temperature and high humidity, causing the screen to turn yellow and the contrast to decrease. Strong impact may also cause it to peel off from the glass. Industrial display use a composite structure: a PET protective film (tear strength > 30N/mm) is added to the surface to resist scratches; a COP film is used to replace the traditional TAC film in the middle layer (lower heat shrinkage and stronger chemical resistance); acrylic adhesive is applied to the back to prevent impact peeling. Actual measurements of an outdoor advertising machine show that the composite polarizer only drops by 2% after running for 1000 hours in an environment of 85°C and 95%RH.

Under strong impact, the wear of the industrial display mostly comes from the internal circuit and backlight module. The solder joints of the circuit board (PCB) may produce microcracks due to vibration, and the backlight guide plate may break, resulting in display defects. Industrial-grade displays are protected by optimizing materials and structures: PCB uses FR-4 (glass fiber reinforced epoxy resin) or high-frequency board, the thermal expansion coefficient is more matched with the chip packaging material, and the cracking of solder joints is reduced; key solder joints are wrapped with bottom filling glue, and the impact strength is increased by 50%; the backlight guide plate is changed to PMMA+glass fiber composite material (impact resistance is 3 times that of ordinary PMMA). After a construction machinery company replaced the light guide plate, the vibration test was normal for 500 hours.

The reliability of industrial display displays is essentially the precise matching of material performance and scene requirements: glass substrates are strengthened to resist impact, sealing materials block water vapor, polarizer composite structures delay aging, and circuits and backlight materials resist vibration. In the future, with the application of technologies such as flexible displays (such as PI substrates) and nano-coatings (such as super-hydrophobic coatings), industrial displays will further break through environmental restrictions, but their core logic is always to achieve improved adaptability to extreme working conditions through material optimization.