When we choose industrial touchscreen processing, we are always confused by some professional terms. Today we will talk about three screen processing methods in the field of industrial displays. Their professional terms are: AG, AR and AF glass treatments

AG stands for anti-glare,, and AR stands for anti-reflective, AF stands for anti-fingerprint. These are specialized coatings that can enhance your touch screen in ways you didn’t even know you needed.

Anti-Glare is a technology or treatment method commonly used in industrial touchscreen and monitors. The screen usually applies a special coating or undergoes special treatment, such as using specific materials or alloys, to reduce the glare of light. Reflection, thereby reducing glare. Anti-glare technology is of great significance to improving screen visibility and user experience, and is an indispensable part of modern display technology. Because of its anti-reflective properties that reduce light reflection, this technology can provide better visual comfort and visibility in various environments, reducing eye fatigue. In addition, anti-glare technology not only ensures that the content on the screen is clearly visible without interference from external light. It also helps improve the contrast and color accuracy of your monitor, making images and text clearer and easier to read. Therefore, it is very important for outdoor display equipment.

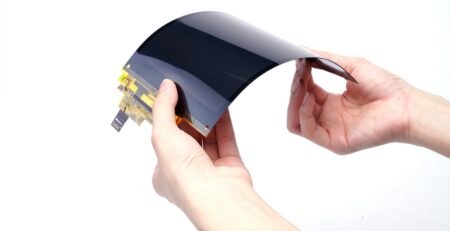

Anti-Reflective refers to another special treatment technology on the industrial touchscreen surface, similar to AG, but more focused on reducing reflections, aiming to reduce the reflection of light on the screen or glass surface. It improves the clarity and readability of images and text on the screen by using a special coating or treatment that reduces the amount of light that reflects from the surface back to the user’s eyes. Displays processed with AR technology can significantly reduce reflections in bright light environments, improving visual clarity and readability. In addition, anti-reflective technology helps improve the contrast and color accuracy of the screen, making the display content more vivid and realistic, making the display suitable for industrial applications in outdoor or other bright environments.

Typically, on high-end monitors and touchscreen devices, these two technologies are used in combination to provide the best visual experience and better visibility in out-of-meeting environments.

AF stands for anti-fingerprint. Resists oil, reduces fingerprints and is easier to clean. Keep your display clear and clean. This technology is commonly used in industrial touchscreen devices and high-end monitors to improve the user experience and the apparent cleanliness of the screen. The application of anti-fingerprint technology makes the screen easier to maintain and clean in daily use, while maintaining the clarity and color performance of the screen. This is especially important for those who use touch screen devices frequently or operate the monitor for long periods of time. No matter how many times you swipe or click, your screen remains clean, which significantly improves the user experience.

Golden Margins –Entire Range of Touchscreen Products

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com