Goldenmargins Co., Ltd. is a manufacturer specializing in full lamination services and industrial displays, industrial all-in-one PCs, and Android all-in-one devices. With capabilities in independent R&D, production, and sales, we are among the leading providers of capacitive full lamination solutions, committed to delivering the most advanced and reliable services that significantly enhance touch performance, brightness, and product appearance.

We offer one-stop optical display lamination, touch panel bonding, and module assembly services. Rooted in the high-end segment of the display industry, we are pioneers in integrated optical bonding solutions.

Product Features

Our touch screen monitor is the ideal daily screen choice for professionals. Designed for demanding industrial environments, it offers a high level of protection, a wide operating temperature range, and efficient fanless passive cooling technology, ensuring long-term uninterrupted stable operation even under extreme conditions. The product utilizes LOCA full lamination technology, significantly enhancing image clarity and viewing angles. Combined with a robust metal-sealed structure and wide voltage & low power consumption design, it delivers exceptional durability and long service life while fully supporting deep functional customization. With sizes ranging from 5 to 86 inches, it can flexibly adapt to your diverse industrial application needs.

IP65 Sealed Protection

Engineered to resist dust, water, and liquid jets, our equipment thrives in demanding settings like washdown areas, humid workshops, and outdoor installations.

Built for Extreme Temperatures

Operate with confidence in the harshest climates, from cold storage (-40°C) to scorching factory floors (up to 80°C).

Fanless & Silent Cooling

Our passive cooling design eliminates fans, reducing power draw, preventing dust buildup, and ensuring zero-noise, 24/7 reliability.

Unmatched Durability & Longevity

Designed for continuous operation, featuring a 50,000-hour LED lifespan, robust resistance to shock/vibration, and key industrial certifications (CE, FCC, 3C).

Tailored to Your Needs

Get a perfect fit with deep customization options for I/O ports, functional modules (RFID, 4G), operating systems, and touchscreen technology.

Superior Optical Clarity with LOCA Bonding

Golden Margins' LOCA technology laminates the display to the glass, delivering crystal-clear visibility, reduced glare, and enhanced durability for bright or outdoor use.

Wide Voltage & Energy Efficient

Withstands industrial power fluctuations (6-36V DC) while its low-power design, including an efficient LED backlight, significantly cuts operational costs.

Robust Metal Construction

A fully sealed metal chassis, toughened glass, and silicone gaskets provide ultimate defense against impacts, scratches, and the elements.

Industrial All-in-one Computer

Featuring a fully sealed and rugged design with an aluminum/magnesium alloy die-cast chassis, this product offers IP65 front-panel protection and supports a fanless cooling structure, ensuring low noise, dust resistance, and long-term stable operation. It provides extensive customization options, supporting a variety of interfaces, functional modules, and operating systems. Equipped with a high-precision multi-touch screen that delivers fast response and glove-friendly operation, it is powered by a low-power wide-voltage industrial-grade processor. Designed to operate in a wide temperature range from -30°C to 80°C, it withstands harsh environments with strong resistance to vibration and interference, making it suitable for diverse industrial applications.

Touch Screen Monitors

Boasting a sturdy aluminum alloy/stainless steel body and an IP65-rated front panel, this device operates reliably in extreme temperatures from -30°C to 80°C. It supports wide-voltage input and various industrial interfaces, while remaining compatible with resistive, capacitive, and infrared touch technologies. Optional functional modules are available for enhanced flexibility. Certified for vibration and interference resistance, it ensures 24/7 continuous operation, guaranteeing long-term reliability in production line environments.

IP65 Touch All-in-One

Featuring a fully-enclosed metal body and reinforced glass panel, this product offers excellent resistance to dust, water, impact, and scratches. Its fanless cooling design and support for wide-temperature and wide-voltage operation ensure stable 24/7 performance even in harsh environments ranging from -40°C to 80°C. It supports both capacitive and resistive touch technologies, accommodating gloved and stylus operation. With a wide range of industrial interfaces and modular expansion capabilities, it is compatible with multiple operating systems and AI edge computing functionalities, making it ideal for high-demand applications such as smart manufacturing, warehousing, and healthcare.

Bar Screen

Integrating a slim design, high customizability, and powerful performance, this display features full lamination technology and a wide-view panel, supporting local dimming and a 120Hz high refresh rate. It ensures stable performance even in extreme temperatures (–30℃ to 70℃), high brightness (800–2500 nits), and IP65-rated environments. With multi-signal input, split-screen display, and touch functionality, it offers optional Power over Ethernet (PoE) support, low power consumption, and a lifespan of up to 50,000 hours. Ideal for various demanding applications such as retail, transportation, and industrial sectors.

Optical Bonding Service

Employing a fully laminated process, it significantly enhances light transmittance to ≥98% while reducing reflectance to ≤1.5%, ensuring exceptional visibility even under strong light. Color contrast is improved by over 30%, delivering deeper blacks and vivid, saturated visuals with a 178° wide viewing angle free of color shift. The touch response delay is ≤3ms with an accuracy error of just ±0.5mm, providing precise and smooth operation ideal for demanding applications. Its reinforced structure offers enhanced impact resistance, along with an IP65 rating for dust and water resistance, and operation in extreme environments from -40℃ to 110℃, ensuring extended durability. Although the unit replacement cost is relatively high, its low failure rate and long-term reliability significantly reduce the overall cost of ownership.

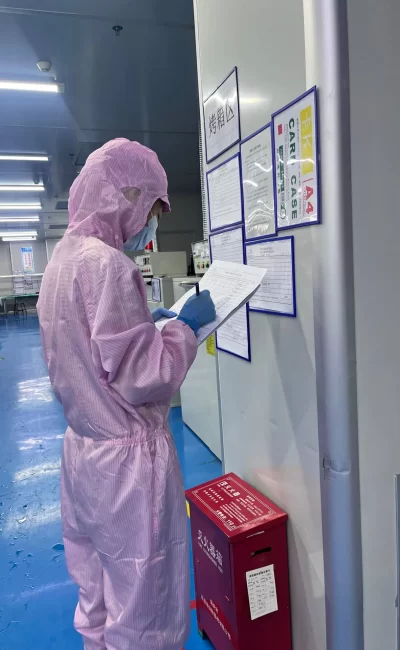

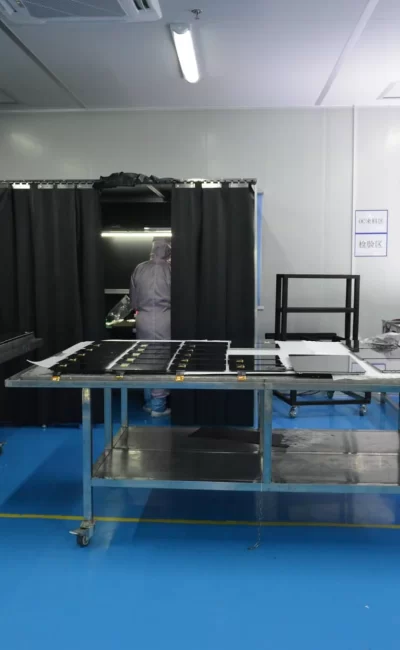

Our Quality Control Process

Our Quality Control Process

At our factory, quality control is built around 100% inspection, ensuring every step—from raw materials to finished products—meets the highest standards. All incoming materials undergo thorough inspection, and only those complying with our stringent quality requirements enter production. Similarly, each product is 100% inspected before shipment to guarantee flawless delivery to our customers.

This “Full Inspection In, Full Inspection Out” approach reflects our commitment to product quality and customer trust. It means we do not rely on random sampling—instead, we take responsibility for every single product, delivering outstanding and reliable performance.